- Joined

- Dec 15, 2012

- Messages

- 150

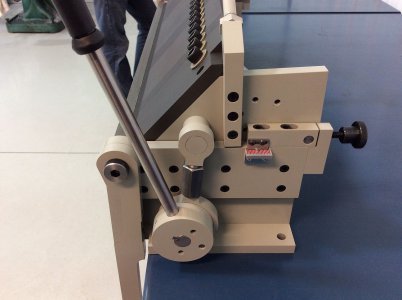

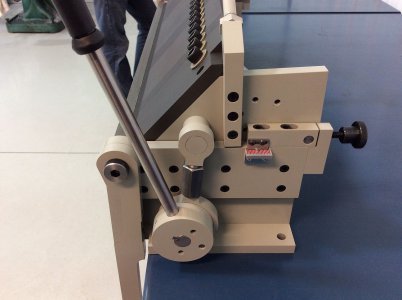

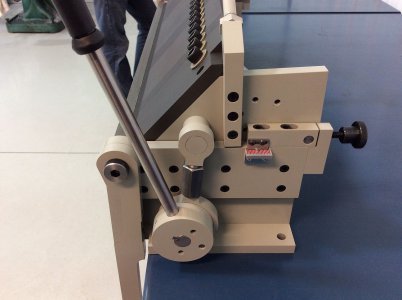

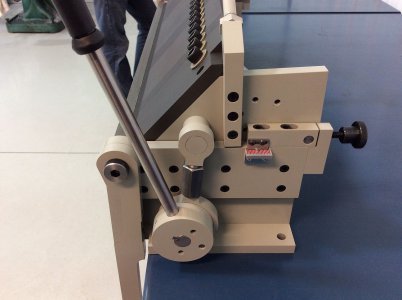

Been working on this for a while now when time was available and more important projects weren't getting in the way. The original design was by Jr. Joe Williams that was modified by Mike Ward and was featured in The Home Shop Machinist as a three part series staring with the March/April 2008 issue. I in turn modified the design to suit my needs and to beef it up a little. In the HSM article the author suggests 20 gauge as the max that you should bend but states as a test he bent a 1/16 piece without much trouble but was really pushing the brake to its limit. I want to be able to do at least 18 gauge if needed so that's where most of the design changes came in.

Heres some pics of the finished break

I have a ton of pics from the project and will post the full build once I get them sorted out.

Heres some pics of the finished break

I have a ton of pics from the project and will post the full build once I get them sorted out.