-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Machine Build Projects

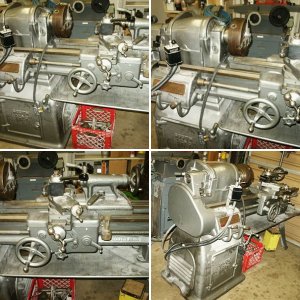

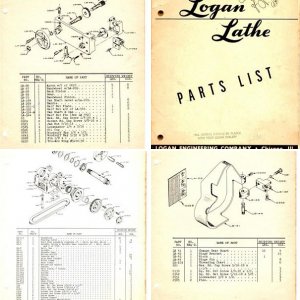

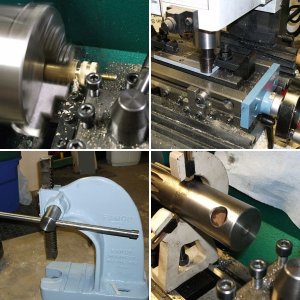

Scraping in all bearing surfaces on my Wards/Logan 10"

PIN

- 39,833

- 73

I've been working on my lathe off and on over the past several weeks or months, but I've been hesitant to start a thread documenting my progress (or lack thereof!) for fear of embarrassing myself. I'm increasingly confident that I'm going to end up with a very precise lathe rather than a very large pile of cast iron dust and tears, so I'm finally willing to share my progress. After creating...

KO-Lee Cutter/Grinder Revamp

PIN

- 31,009

- 93

Perhaps you've seen this from other photos... It's a KO-Lee cutter grinder. It's a good platform and the table and all mechanisms are in excellent condition. I don't think this machine was used much in it's lifetime as there are very few signs of wear (hardly any at all really). The motor is the weak link. The bearings are going bad and vibration can be felt in the short shaft. The...

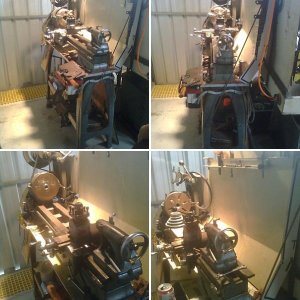

Restoring an old powered hacksaw

Jul 29

- 22,419

- 68

Figured I'd share my restoration project! I've always found these old machines quite cool and when a neighbour offered me a defective one for free, I couldn't say no!  This is the machine as I got it, it runs but won't lower the sawblade so you have to manually push it against the work piece, which becomes quite the challenge and dangerous as heck when it's moving back and forth. The...

This is the machine as I got it, it runs but won't lower the sawblade so you have to manually push it against the work piece, which becomes quite the challenge and dangerous as heck when it's moving back and forth. The...

9A project completed

Sep 11

- 34,220

- 66

Some of you guys may remember this little crudball I acquired back in April... I had just completed the last project, the Seneca Falls #30 resto-mod,(project of the month) when this lathe found it's way to me via a friend of a friend. My friend, who is also a tool salesman, showed me a pic of this on his phone, which came from his friend, the seller, who now is a retired tool room...

Clausing 1771 Drill Press Restoration

Dec 23

- 22,849

- 31

I picked up a Clausing variable speed drill press from a Craigslist ad. I offered the guy $200.00 and he accepted. The drill press was in decent overall condition, and had a new motor on it. I disassembled the machine and cleaned up and painted everything. Mechanically, it was in very good condition, and the only real repair work I did was to straighten a few of the handle arms. One...

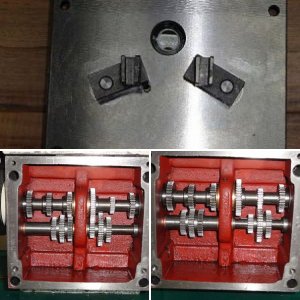

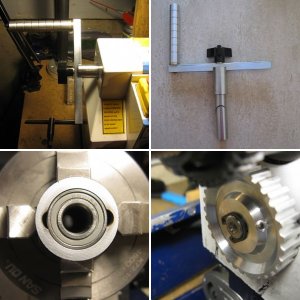

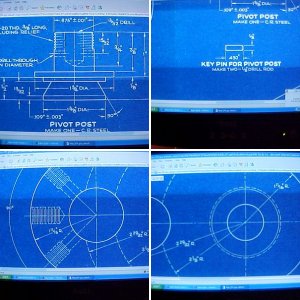

Erich's Benchtop Gear Hobber Project

PIN

- 29,237

- 182

Inspired by @vtcnc and others, I've decided to make my next project a benchtop gear hobber! I opted to buy from Martin Models (see my thread here: https://www.hobby-machinist.com/threads/visited-martin-models-today.101648/ for my trip report), which seems like a nice revision of the standard kit with some nice looking options/changes. Also, it comes with some plans that are seemingly not...

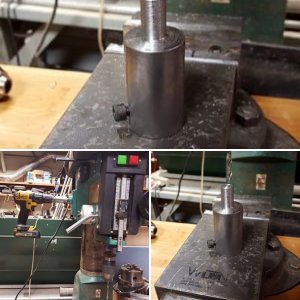

Home Built Die Filer

PIN

- 17,127

- 26

I started this about six months ago. I'd seen pictures of the Pine Grove (MLA-18). I decided I didn't want to spend quite that much, so after talking to Andy at Pine Grove, I had him send me the drawings and decided to try to build one out of materials I had on hand rather than use his beautiful casting kit. This is what I ended up with. Here's a video of it running.

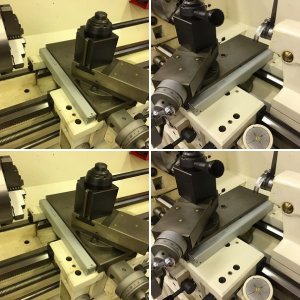

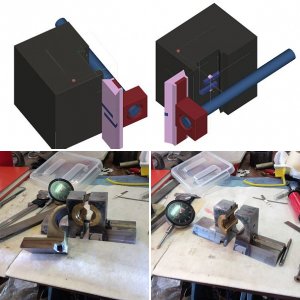

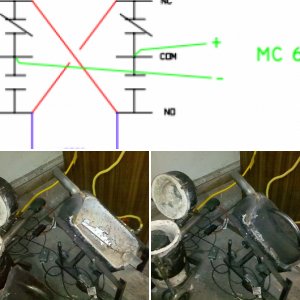

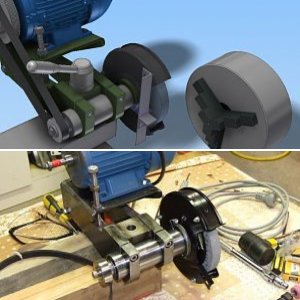

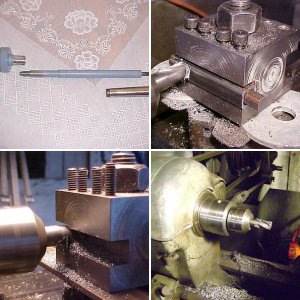

Home-made CNC lathe using servos

PIN

- 28,205

- 38

This is a thread about CNC Lathe I recently built. This is my first CNC machine, and obviously, I’m not a CNC guru. Being an engineer, I prefer more practical ways of making things rather than R&D approach with investing plenty of time, money and energy. This is also why I use simple and robust ideas instead of diving deep into unique ones and solving the problems just created. I started...

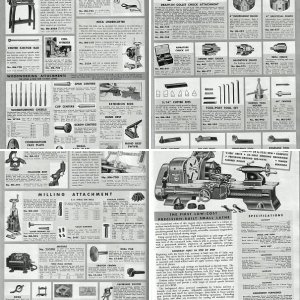

Metal Lathe Accessories is Here to Stay!

Jan 04

- 107

- 4

Hi Everyone, My name is Jared Pilch (Co-Owner of Metal Lathe Accessories) and I sent out the below mass email to as many of our MLA customers as I could find. However, I am sure that I missed some and that is why I am posting it here as well! My bother Jack and I are thrilled to have joined this community and look forward to learning as much as we can! As some of you are aware, Andy...

CNC Lathe Build

Sep 26

- 9,912

- 20

The gear hobber project is on hold for awhile. I've decided, for various reasons, that I need (no, no, no - not want, but need) a CNC lathe. I will spare you the long ranging logic behind my reasons for building a CNC lathe from scratch, but suffice to say it boils down to money and what I think I need.

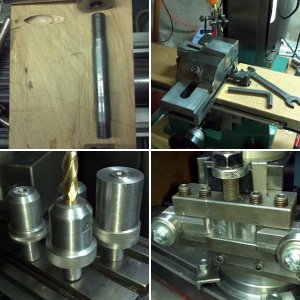

My slow speed diamond disc lapping machine, the beginning

Apr 17

- 42,517

- 92

I have all the materials. The idea is to mount this 90 RPM drive motor on the 1/2” aluminum plate. There will be an 8” lapping disc that will register on a hub on the wheel. Magnets will hold the disc to the plate. An adjustable tilt platen will allow for precise angles to grind high speed tool, carbide blades for scraping or brazed carbide cutting tools. The discs come in grits from 250 to...

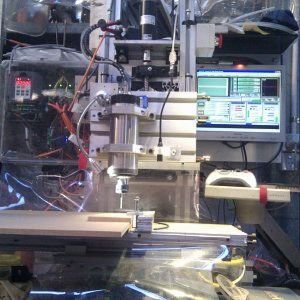

Bridgeport CNC with Masso Controller/Clearpath

Oct 08

- 54,775

- 166

This is going to be my first CNC build and my First build log. I've decided that a build log on this forum might be a good idea for this project so the next guy to take on this project doesn't have to deal with the stupid stuff I'm already running into. This is my Masso Controller I will be using 3 Clearpath Stepper Killer servos model# CPM-SDSK-3432S-RLN They are a little over 6" long...

Shop build beast of a chop saw

Jan 27

- 4,617

- 29

I started this build couple of months ago thinking i'll finish it in a week or two so i continued writing about it in the question & answer section where i had couple of questions, but because is drag on for so long i've decided to move it in the project section.

Joel Miller Cnc Milling Machine

Apr 24

- 7,894

- 5

Original at http://jmillerid.com/wordpress/category/cnc-milling-machine/ CNC mill phase 1: planning Thursday, 9 June 2011 While I have understood the basics concept of CNC machining–and have utilized it in my work–I never fully appreciated how complex a system a CNC machine is until I set about designing and building one. There are many software and hardware layers are involved in the...