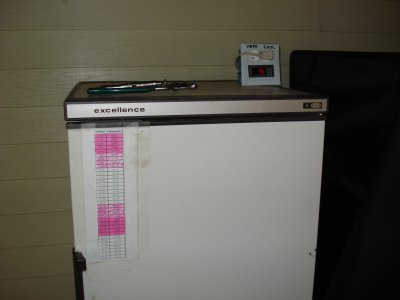

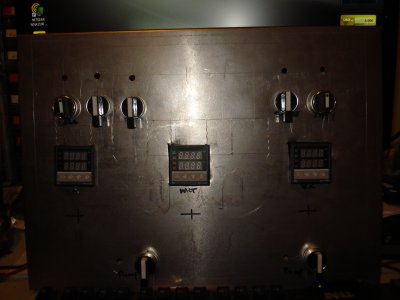

The Hop garden was a dissappointment last year. Of the nearly 20 rhizomes I planted only three broke ground and were spindly and weak. I had planned to do some intensive composting and soil building during the off season and replant new rhizomes this year. I think the failure was mostly, like 99% gardener failure and the rest was probably my fault. I didn't get the load of compost turned this winter that I expected either. My health kept getting in my way. So I didnt get the amendments done to beef up the soil so I will hold off on the rhizomes till next deason and work on the dirt through the summer. I did manage to get the Keezer, controller and most of the control panel done. The tower is nearly complete, just some minor sheeting and finish mounting hardware. Slowly but surely it is coming together even when I have to work around my kidneys and my lungs. I still havent decided how I want to plumb it. I have everything set up with SS QD camlocks now, but I was thinking of hard piping the tower and running a short SS covered flex line to each vessel. It would create a lot of bacterial opportunities though so I am kind of still working that out to minimize the connections and smoothe all of the bends so Bacteria wont have all the nooks and crannies to hide in inside the plumbing. Still a work in progress, but I have had a ton and a half of fun designing and building it and working with the soil too. Keeps me grounded, even when I am having a bad day I am reminded how insignifigant it all really is in the grand scheme of things...

Bob

P.S. You can send any spare hops you get my way anytime....