- Joined

- Feb 17, 2013

- Messages

- 4,406

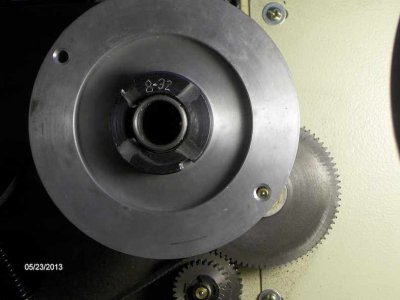

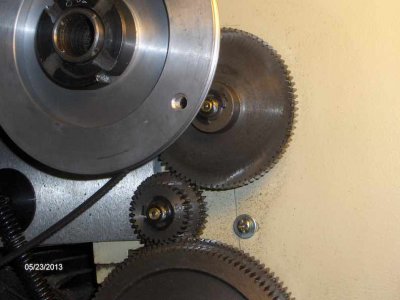

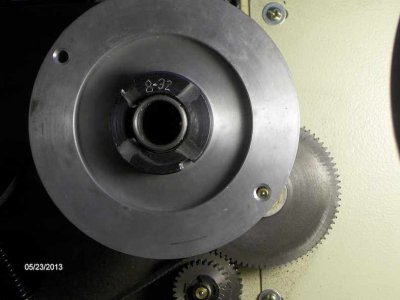

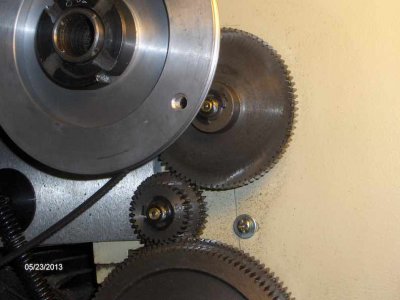

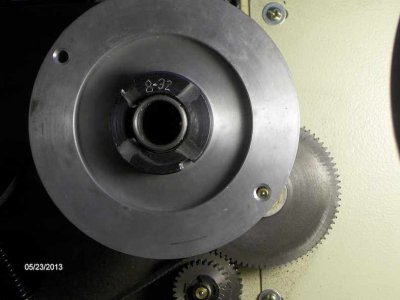

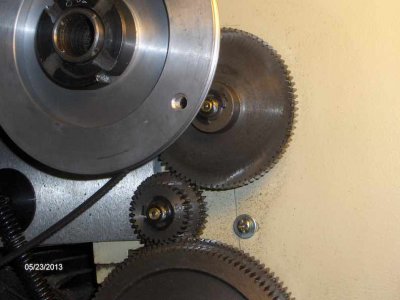

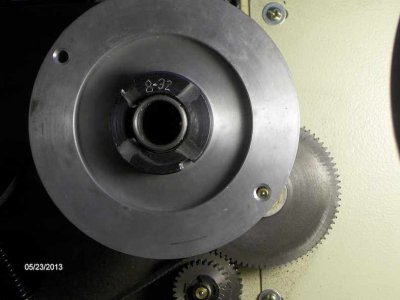

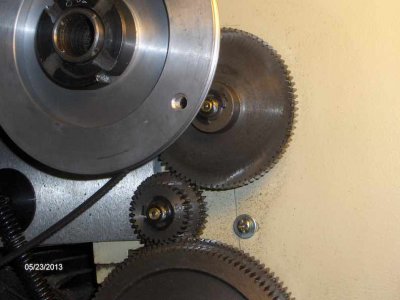

I just bought a used Grizzly G4000 and have started cleaning it up, etc. I noticed that one of the lube points is obscured by the aluminum pulley on the spindle. The first photo shows how the lube point can be accessed, though at enough of an angle (maybe 40 degrees or so) that the tip of the oiler can't "seal" well, and you'll get a major drool when trying to oil it.

Luckily, the G4000 uses a very small section belt, so the grooves in the pulley aren't very deep. I solved the problem by drilling a 1/4" hole through the pulley, centered 1/4" inward from the outer edge. The hole is large enough to allow access to the lube point, but small enough that it doesn't break into the belt groove. Just to be OCD about it, I actually drilled two holes 180 degrees apart - wouldn't want there to be any imbalance when spinning the chuck!:rofl:

Luckily, the G4000 uses a very small section belt, so the grooves in the pulley aren't very deep. I solved the problem by drilling a 1/4" hole through the pulley, centered 1/4" inward from the outer edge. The hole is large enough to allow access to the lube point, but small enough that it doesn't break into the belt groove. Just to be OCD about it, I actually drilled two holes 180 degrees apart - wouldn't want there to be any imbalance when spinning the chuck!:rofl: