- Joined

- Jul 26, 2011

- Messages

- 4,142

There seems to be a lack of sufficient pictures of projects posted by members of the forum. Hey! Let's see your work!!

There seems to be a lack of interest and response in them so the efforts are futile.

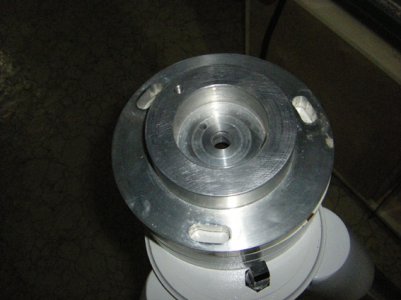

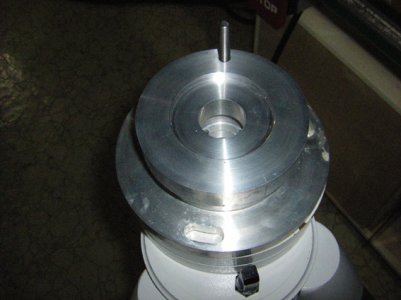

I was going to post in the what you did today thread but I'll throw them in here. I am very green with my lathe or any machining for that matter. I made up a 9/16ths dimple die just to "play around on the lathe" plus now I can try to dimple some sheet metal.

View attachment 63042View attachment 63044Mike