- Joined

- Jul 27, 2013

- Messages

- 295

Next little project;

I should be looking ahead and getting all of my reassembly projects lined up so that everything that needs fixing is all done when it is time to put it on. Well... I haven't been doing that, so every step has its surprises and delays as a result. The next little project will be the drive box cover brackets. Those of you who remember the wreckage inside the headstock will not be surprised by this either. One of the brackets was obviously broken at some point, and someone made an attempt at making a new one.

Some broken items on this poor thing have been quite well repaired over the years, and some not so much. These cover hinges LA-384 are yet another example of the not so much. You can see that the replacement version was a bit of a loose interpretation of the original. Among all the obvious faults, you can clearly see that with the pivot pin holes lined up, the mounting bolt holes clearly do not. I would imagine that it is kind of hard to get the cover lined up nicely if the brackets are not the same. I initially thought about welding up some of the holes and re-drilling them, but that doesn't do anything for the odd narrow pivot head on the homey made one. I guess in the end I might as well just make a new one of my own instead of settling for someone else's inadequacies. Another chance to make something is not a bad thing to me.

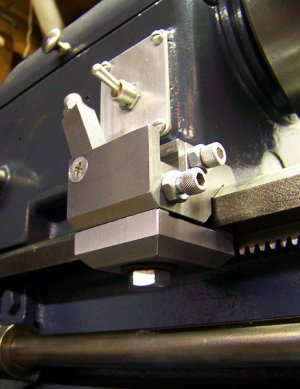

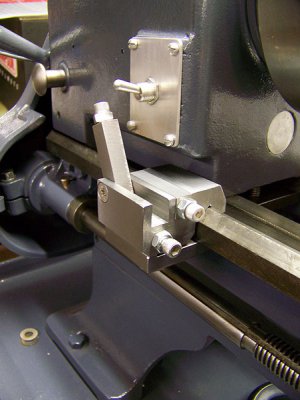

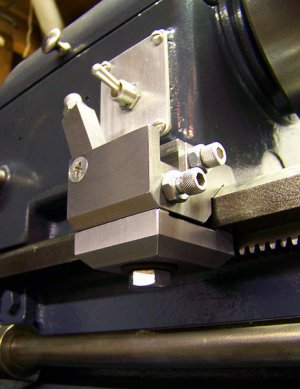

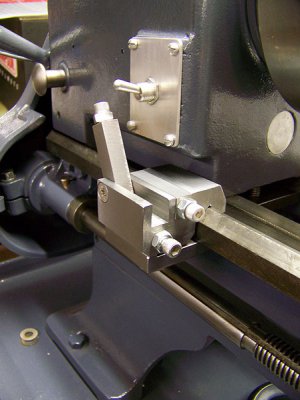

This worked out well, I think. I'm trying not to deviate too far from what was original, but the latches these came with were wholly inadequate, evidenced by the fact that so few of them exist. I think this constitutes a reasonable upgrade!

I should be looking ahead and getting all of my reassembly projects lined up so that everything that needs fixing is all done when it is time to put it on. Well... I haven't been doing that, so every step has its surprises and delays as a result. The next little project will be the drive box cover brackets. Those of you who remember the wreckage inside the headstock will not be surprised by this either. One of the brackets was obviously broken at some point, and someone made an attempt at making a new one.

Some broken items on this poor thing have been quite well repaired over the years, and some not so much. These cover hinges LA-384 are yet another example of the not so much. You can see that the replacement version was a bit of a loose interpretation of the original. Among all the obvious faults, you can clearly see that with the pivot pin holes lined up, the mounting bolt holes clearly do not. I would imagine that it is kind of hard to get the cover lined up nicely if the brackets are not the same. I initially thought about welding up some of the holes and re-drilling them, but that doesn't do anything for the odd narrow pivot head on the homey made one. I guess in the end I might as well just make a new one of my own instead of settling for someone else's inadequacies. Another chance to make something is not a bad thing to me.

This worked out well, I think. I'm trying not to deviate too far from what was original, but the latches these came with were wholly inadequate, evidenced by the fact that so few of them exist. I think this constitutes a reasonable upgrade!