- Joined

- Dec 17, 2012

- Messages

- 630

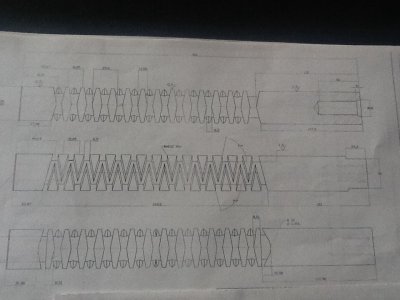

finished my mini lathe leadscrew handwheel using the tailstock wheel. my original thought was i could then remove the carraige handwheel, as its always in the way of the cross slide wheel (or vice-versa),but man, is it really slow! i remove the change gear on the left side of the leadscrew when i use it, which lets it turn freely and quieter.maybe later on ill use a gear setup to make the crank a little faster.

I did that mod on mine before I swapped out for a longer bed. If I do it again, I will just make a wheel that goes onto the other end of the leadscrew instead. Just take off the drive gear and attach it there.