- Joined

- Sep 29, 2013

- Messages

- 130

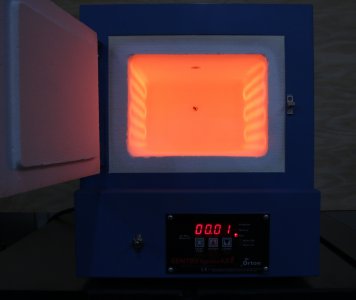

Ok, I am way out of my comfort zone here. I know nothing about heat treating, but would like to learn. So, would this Paragon furnace be suitable for things like heat treating DIY taps and dies? Also, would it work for treating things like DIY 1-2-3 blocks before surface grinding? It looks like the Max Temp is 2000 degF and the interior dimensions are 8" x 7.75" x 5.75" Thanks for your help!

Bob

Furnace for sale on Craigslist: http://fairbanks.craigslist.org/art/4638110649.html

Furnace info at Paragon WebSite: http://www.paragonweb.com/SC2.cfm

Bob

Furnace for sale on Craigslist: http://fairbanks.craigslist.org/art/4638110649.html

Furnace info at Paragon WebSite: http://www.paragonweb.com/SC2.cfm