-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

- Forums

- THE PROJECTS AREA

- PROJECT OF THE DAY --- WHAT DID YOU DO IN YOUR SHOP TODAY?

- Project of the Day Mega-Thread Archives

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

2014 POTD Thread Archive

- Thread starter Smudgemo

- Start date

- Joined

- Dec 19, 2012

- Messages

- 41

I was thinking the same thing. I think hockey pucks will work.

Just did some shop searching. these are what I found.

that should do it.. mobile and locking. Good idea!

- Joined

- Oct 17, 2013

- Messages

- 363

I would not have any trouble on a rotary table either. CNC is definitely quicker thought.That's pretty, nice lines.

I could do it on a rotary table, but it would be a lot of work. I find myself designing much more complex shapes since I bought my CNC. Back in the hand crank days (not that long ago), I kept things pretty simple.

- Joined

- Mar 10, 2013

- Messages

- 324

very clever idea to save space!! what do you have planned for the electrical plugs?

I have a habit to unplug items not in use.

As far as the cords I will just coil the cords on the grinders

- Joined

- Apr 23, 2011

- Messages

- 2,476

1/2" x 12 = standard whitworth thread, (BSW)......weird thread, best I could measure was 1/2-12. A 1/2-13 bolt wont go in the holes and neither will any similar sized metric bolt......]

Cheers Phil

1/2" x 12 = standard whitworth thread, (BSW).

Cheers Phil

I had no idea! thank you!

- Joined

- Apr 23, 2011

- Messages

- 2,476

Actually, I just thought your taste in indoor plants was rather gauche12bolts will vouch for its veracity

Cheers Phil

- Joined

- Apr 23, 2011

- Messages

- 2,476

I've wanted to make this space saving stand for some time. I cant remember where I got the idea.

Do you use the grinders on the bench and then store them on the stand?

Cheers Phil

- Joined

- Mar 10, 2013

- Messages

- 324

Do you use the grinders on the bench and then store them on the stand?

Cheers Phil

On the top of the stand, but I just thought if I need to use 2 at a time I could set one in my vise too .

- Joined

- Mar 10, 2013

- Messages

- 324

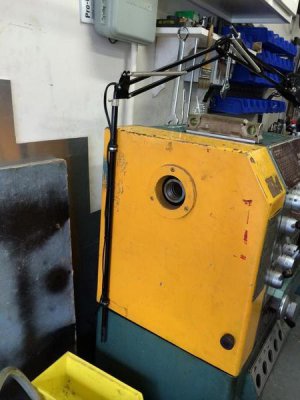

I mounted the casters on the grinder stand today. I had to get a friend to machine a set of spacers as my lathe is down for repairs.

I also had time to mount one grinder to a plate. The working height is 43 inches just perfect for me.

This is my light duty course stone grinder in the pic. It's a rebuild from spare parts.

I also had time to mount one grinder to a plate. The working height is 43 inches just perfect for me.

This is my light duty course stone grinder in the pic. It's a rebuild from spare parts.