Hi Guys,

I've been registered with this forum about a year now. I'm fairly new to machining, only been doing it as a hobby for the last three years or so. I would like to share some of the more interesting projects I've worked on for the last couple years.

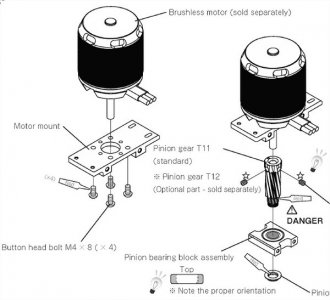

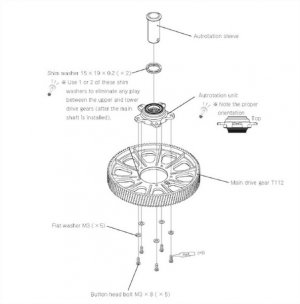

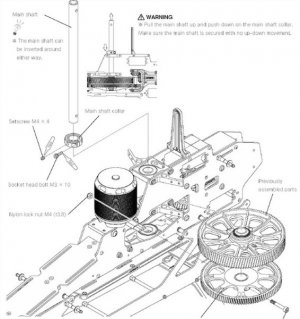

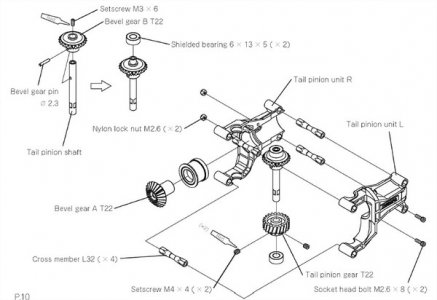

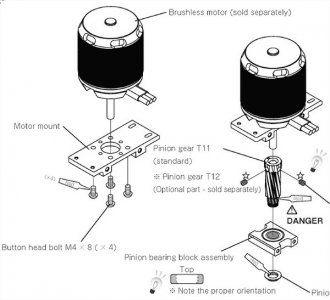

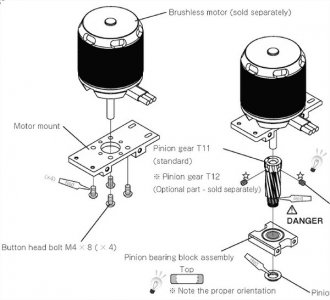

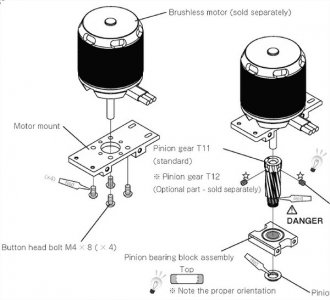

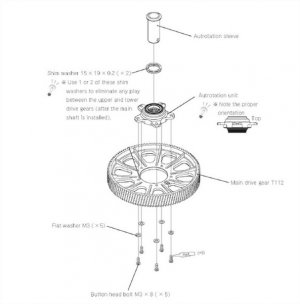

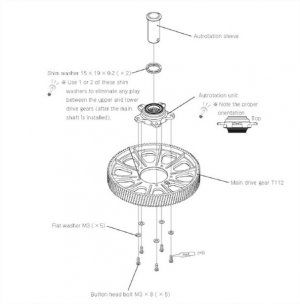

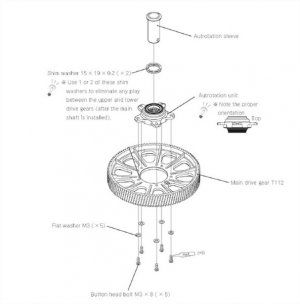

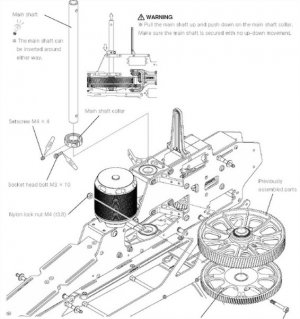

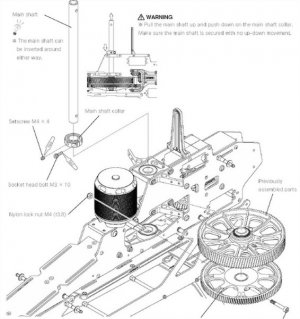

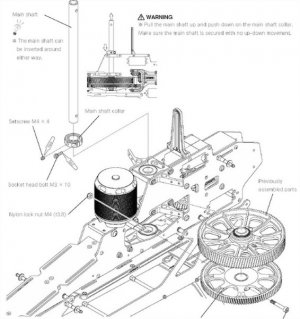

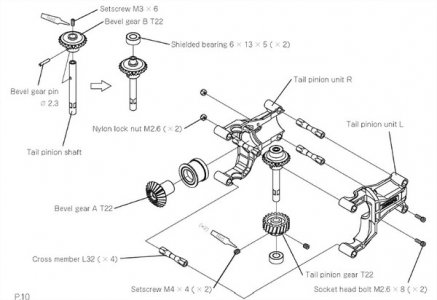

This mount will convert the Miniature Aricraft USA Stratus/Spectra airframes from Nitro/Gasoline respectively over to electric power. It essentially replaces the clutch stack and the electric motor occupies the area once filled by the internal combustion motor.

It incorporates bolt patterns for all motors currently available for 90 size electric machines making it very flexible. The elegant shape raises the motor close to the main gear so that the motor shaft is kept very short. The diamond profile and sloped edges help to keep the weight down without having to drill unsightly holes all over the part.

The below was the first one of this part sent out to a customer. It was made on my Taig CNC Mill

These are pictures of a prototype being test fitted. This did not have the mounting holes drilled in the flanges, since it was just to debug the program.

The most challenging thing in this part was getting everything aligned when I flip the part over to machine the reverse side.

For that I made up an indexing jig that allows me to locate the part very precisely via dowel pins.

Chevy

I've been registered with this forum about a year now. I'm fairly new to machining, only been doing it as a hobby for the last three years or so. I would like to share some of the more interesting projects I've worked on for the last couple years.

This mount will convert the Miniature Aricraft USA Stratus/Spectra airframes from Nitro/Gasoline respectively over to electric power. It essentially replaces the clutch stack and the electric motor occupies the area once filled by the internal combustion motor.

It incorporates bolt patterns for all motors currently available for 90 size electric machines making it very flexible. The elegant shape raises the motor close to the main gear so that the motor shaft is kept very short. The diamond profile and sloped edges help to keep the weight down without having to drill unsightly holes all over the part.

The below was the first one of this part sent out to a customer. It was made on my Taig CNC Mill

These are pictures of a prototype being test fitted. This did not have the mounting holes drilled in the flanges, since it was just to debug the program.

The most challenging thing in this part was getting everything aligned when I flip the part over to machine the reverse side.

For that I made up an indexing jig that allows me to locate the part very precisely via dowel pins.

Chevy