Jamie,

I just sent you the JPG of the Timken logo with Tapered Roller.

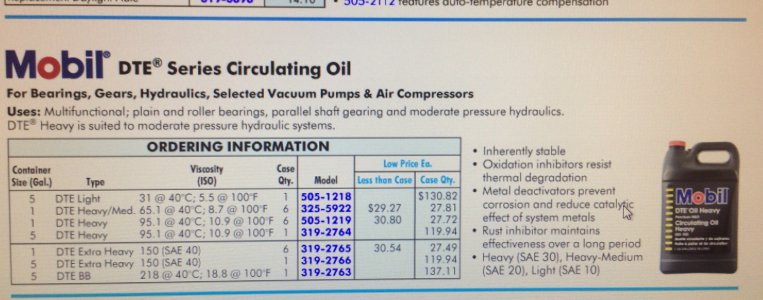

Sometime after 1956, Atlas changed the oil viscosity recommendation for all machines from SAE 10 to SAE 20. The Mobil DTE Heavy Medium @ ISO 65.1 is equivalent. And is what I've been using for the past three or four years. I use it everywhere except on gear teeth (where I am still using a can of Lubriplate from the last Century) and the ways, where I use Way Oil, mainly because one of the eBay sellers who sell felt oilers had one ad where they bundled four with a small squeeze bottle of Way Oil. Both the oil and the squeeze bottle seem to work well.

On cutting oil, I wouldn't know where to start. There are too many variables. It depends upon what you are cutting, what you are cutting it with, ambient temperature, phases of the moon. national debt, and probably a bzillion other factors. Fortunately, there aren't too many cases where what you use can make matters worse.

Robert D.