B

BRIAN

Forum Guest

Register Today

OK so its back to work

Looking around I found I had to many half finished job so I got into clearing up some of them.

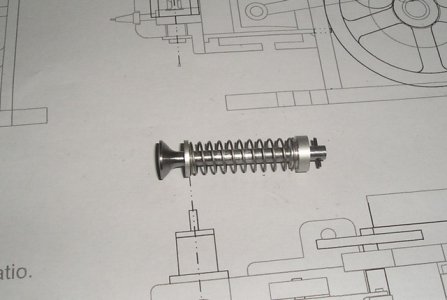

The intermediate timing gear did not have a shaft so one was made and the gear planted.

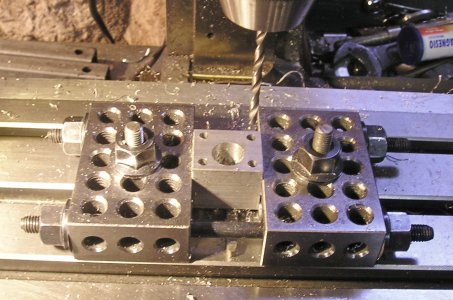

the side plates had to be milled out to take the bearing retainer plates that I had not made yet??

So that had to be done.

Also the piston was not finished the blank had been made early on and lapped to the cylinder

but I kept making excuses to my self that I had not ordered the rings. so it was put to one side ( I still haven't ordered them ) "Do other's do this" ,

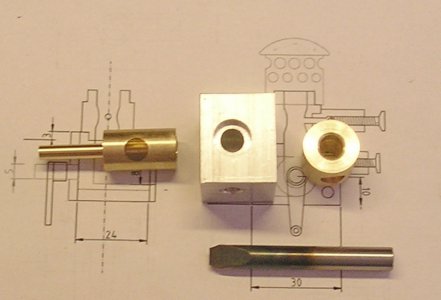

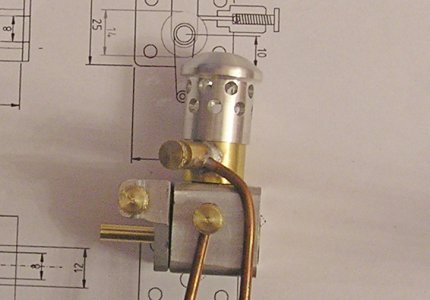

So find the blank and drill the wrist pin hole.

Turn the inside of the skirt.

Then mill out the recess for the small end,

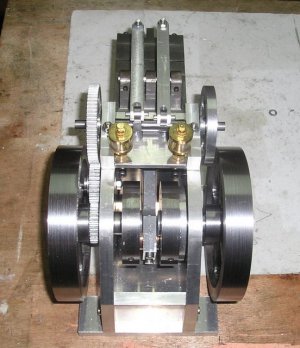

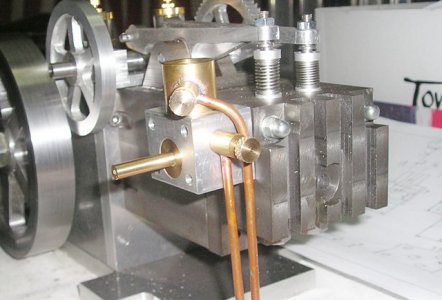

Now fit it all together to see how it fits,

That looks Better.

Brian.

Looking around I found I had to many half finished job so I got into clearing up some of them.

The intermediate timing gear did not have a shaft so one was made and the gear planted.

the side plates had to be milled out to take the bearing retainer plates that I had not made yet??

So that had to be done.

Also the piston was not finished the blank had been made early on and lapped to the cylinder

but I kept making excuses to my self that I had not ordered the rings. so it was put to one side ( I still haven't ordered them ) "Do other's do this" ,

So find the blank and drill the wrist pin hole.

Turn the inside of the skirt.

Then mill out the recess for the small end,

Now fit it all together to see how it fits,

That looks Better.

Brian.