- Joined

- Feb 7, 2013

- Messages

- 2,485

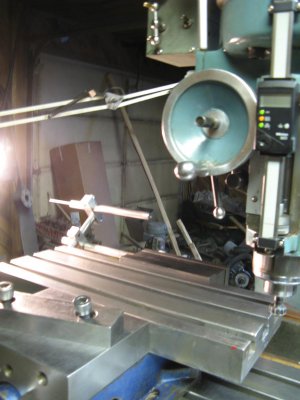

The T-Slot cutter made from an old truck axle proved out nicely and seems no worse for

wear than when I started this project. First I made a number of passes with a 5/8 inch 2 flute

HSS end mill and then followed that with the T-Slot cutter. I have had this big chunk of

steel for a few years and added the middle slot in it just yesterday. Also one does not ever

seem to have enough T-Nuts so made 10 of them so I have a supply. Here's a couple photos

of the work.

wear than when I started this project. First I made a number of passes with a 5/8 inch 2 flute

HSS end mill and then followed that with the T-Slot cutter. I have had this big chunk of

steel for a few years and added the middle slot in it just yesterday. Also one does not ever

seem to have enough T-Nuts so made 10 of them so I have a supply. Here's a couple photos

of the work.