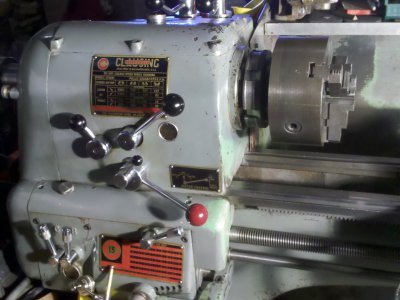

I recently acquired a CC 13x36 lathe. It was filthy but now it is clean, painted, and running. I'm learning it, slowly. Today a friend brought me a job that requires turning down a 1.125 shaft to 1.00 about two inches on one end and threading that end to 16tpi. Same for a second shaft except left-hand threads. I know how to thread and have do so many times on my recently sold SB11".

As this is my first threading job on the CC I'm practicing on some scrap. It seems that no matter where I place the various levers I get very fine threads like 32tpi.

What am I doing wrong?

As this is my first threading job on the CC I'm practicing on some scrap. It seems that no matter where I place the various levers I get very fine threads like 32tpi.

What am I doing wrong?