- Joined

- Mar 26, 2014

- Messages

- 211

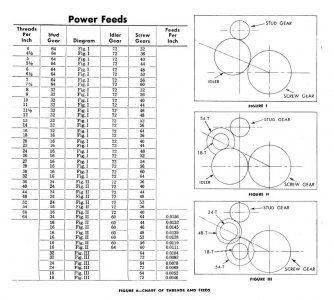

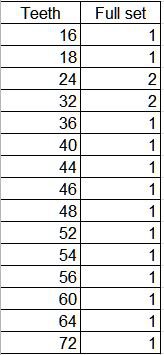

Good evening. I have a Logan 200 with a couple of issues. They may be a lack of knowledge on my part. The lead screw speed seems to be a bit fast. I can't really get a good finish, it looks kind of like threads although very close together. The gear on the lead screw is 72 teeth. The gears on the idler are 60 and 32 teeth. Does that seem like a good speed?

Also I can't remove the 3 jaw chuck. I'd like to install the 4 jaw but don't want to damage anything getting the chuck off. Thanks

Also I can't remove the 3 jaw chuck. I'd like to install the 4 jaw but don't want to damage anything getting the chuck off. Thanks