- Joined

- Feb 2, 2013

- Messages

- 3,609

i had a funny incident while working on the planer's blade.

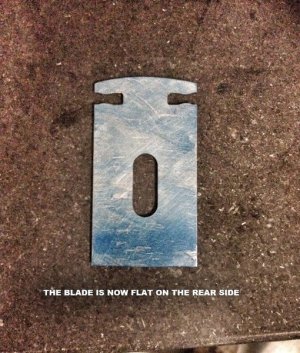

i was flattening out the blade and had an instant of DUH----

i was peining the blade with a Ball-Pein hammer(the actual use of the Pein part of the hammer!!!)

to relieve the stresses and make the blade act right -

Wrong Choice...

the blade fractured when i got a little too close to a relief hole

.

.

a step backwards, but not for long.

i already went back to HF and got another plane and robbed it's blade to put into Brav65's plane

i had other super coupons and got more free junk

anyway, the project is coming along -slowly still, but i thought i'd share my screw up.

i was flattening out the blade and had an instant of DUH----

i was peining the blade with a Ball-Pein hammer(the actual use of the Pein part of the hammer!!!)

to relieve the stresses and make the blade act right -

Wrong Choice...

the blade fractured when i got a little too close to a relief hole

a step backwards, but not for long.

i already went back to HF and got another plane and robbed it's blade to put into Brav65's plane

i had other super coupons and got more free junk

anyway, the project is coming along -slowly still, but i thought i'd share my screw up.