-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Hot Hot Is Too Hot...

- Thread starter cdhknives

- Start date

- Joined

- Nov 17, 2014

- Messages

- 173

Definitely going to be doing this upgrade on both my atlas 10s.

- Joined

- Apr 12, 2013

- Messages

- 562

I guess I missed something while cleaning up this lathe and bringing it back into service. I'm fairly certain this shaft was smooth when I cleaned out all the hardened grease. It has been slinging more and more black grease...it goes in red (Mobil 1 synthetic axle grease) and comes out black and of significantly lower viscoscity. They are definitely getting warm...even hot to the touch these days and that was not happening 6 months ago.

Some measurements for ya...with my harbor freight micrometer:

Shaft nominal diameter: 0.750"

Diameter of raised lip: 0.752"

Diameter under bearing: 0.742"

Nothing obvious on the bearing needles except a single line near the bottom of the picture where it is matte, not shiny. The inside of the housing is ROUGH. Ugly rough. Pics:

Some measurements for ya...with my harbor freight micrometer:

Shaft nominal diameter: 0.750"

Diameter of raised lip: 0.752"

Diameter under bearing: 0.742"

Nothing obvious on the bearing needles except a single line near the bottom of the picture where it is matte, not shiny. The inside of the housing is ROUGH. Ugly rough. Pics:

- Joined

- Dec 12, 2011

- Messages

- 132

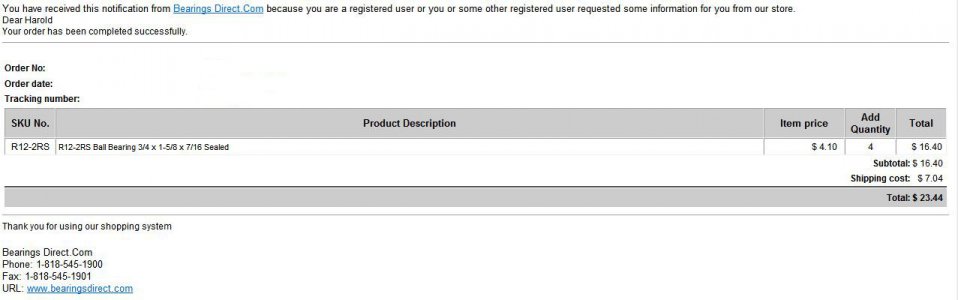

Yes they are 6061 that I had on hand. They are probably a built little heavier then needed but they have worked great for 2 years now. Here is info on the bearings I used.WH, what material is that? Aluminum? Sealed bearings don't wear the housing, so Al would be much easier and faster to machine on a dying lathe!

WH

- Joined

- Dec 12, 2011

- Messages

- 132

I did a quick ACAD sketch at lunch...look reasonable? 2" wide may be a problem with spacing between the 2 groove and 4 groove pulley.

Your measurements are reasonably close to mine. I am actually at 2.18 wide and 2.25 diameter, but like I said I thought I was a going a little big. The one thing you have to watch is that the center relief groove

leaves enough clearance for the "C" shaped carrier in the back of the "C" to allow for belt adjusting. I am showing 2.6" between the faces of the two pulleys so plenty of room there. I mostly did it as a cut and try as I had a spare assembly to play with.

WH

![IMG_3068 [Desktop Resolution].JPG IMG_3068 [Desktop Resolution].JPG](https://www.hobby-machinist.com/data/attachments/56/56006-2e7dabd313a6f5c82a64aa8c39611a0a.jpg)