- Joined

- Jan 3, 2015

- Messages

- 400

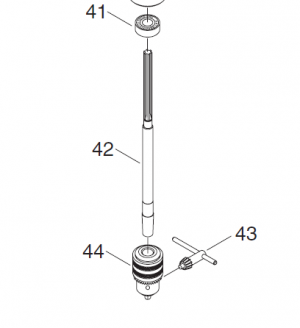

I've had one of these drill presses for quite a while, and have lived with a lot of runout for that time. The end of a drill bit wobbles a lot. I don't have a good long tool rod, but a 3/8 drill bit as far down as the shank extends (an inch?) below the chuck has 10 mils of TIR.

I thought I'd re-seat the taper, it's a JT-33 taper, but I can't get it out. I was thinking the taper may have had some gunk in it when I set it, and it ended up at an angle. 10 mils seems like a lot even for a no name chuck.

How can I pull the chuck out of the taper? There's no way to go in through the top and tap it out with a hammer, so it's going to end up having to be pulled down at the chuck.

This is possibly a general machining question, but all help appreciated.

Thanks,

Bob

I thought I'd re-seat the taper, it's a JT-33 taper, but I can't get it out. I was thinking the taper may have had some gunk in it when I set it, and it ended up at an angle. 10 mils seems like a lot even for a no name chuck.

How can I pull the chuck out of the taper? There's no way to go in through the top and tap it out with a hammer, so it's going to end up having to be pulled down at the chuck.

This is possibly a general machining question, but all help appreciated.

Thanks,

Bob