- Joined

- Dec 14, 2013

- Messages

- 167

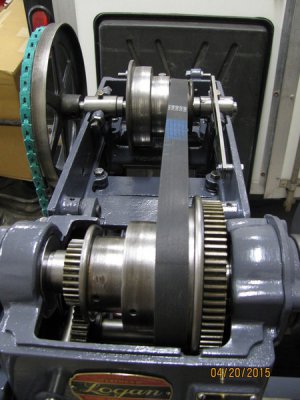

Today I assembled the tail stock and put it on the lathe. I aligned the stamped indicator marks on the base and housing and called it good for now. I'll fine tune it with a test bar when I get the lathe running.

Next, I installed the name plate and temporarily installed the switch plate with only two screws to see what they look like.

First, I'll say I have zero experience restoring name plates. On the name plate, I cleaned the plate with lacquer thinner, used Testor's model paint, and painted the red and black bars. Then, I wet sanded the paint until the raised letters and marks appeared. I then tried to spray clear over the top which turned out to be a mistake. The clear lifted the colors below. I left it to dry completely while I worked on other parts. I wet sanded the wrinkles, rubbed with some polishing compound, and applied some car wax. I could have completely stripped it with lacquer thinner and started over but that aint gonna happen. I'm calling it good.

I cleaned the switch plate the with lacquer thinner and this time sprayed it with Rustoleum black. I sprayed enough to cover the plate but not too much so it wouldn't build up and/or run. I let it dry a couple days and baked it at 12o degrees for 20 minutes. I lightly wet sanded until the raised letters and borders were clean, used polishing compound to finish it before using a little car wax. No clear this time. I think it came out much better and wish I would have done the name plate the same way. Lesson learned. The little bit of exposed brass around the switch hole is covered by the switch retaining ring. I hope this helps anyone else who tries to do this. Forget the model paint and clear and use the rattle cans.

I think it's safe to say I'm done with name and switch plates and will start on the reverse shifter and motor and countershaft box next.

That's it for now.

Next, I installed the name plate and temporarily installed the switch plate with only two screws to see what they look like.

First, I'll say I have zero experience restoring name plates. On the name plate, I cleaned the plate with lacquer thinner, used Testor's model paint, and painted the red and black bars. Then, I wet sanded the paint until the raised letters and marks appeared. I then tried to spray clear over the top which turned out to be a mistake. The clear lifted the colors below. I left it to dry completely while I worked on other parts. I wet sanded the wrinkles, rubbed with some polishing compound, and applied some car wax. I could have completely stripped it with lacquer thinner and started over but that aint gonna happen. I'm calling it good.

I cleaned the switch plate the with lacquer thinner and this time sprayed it with Rustoleum black. I sprayed enough to cover the plate but not too much so it wouldn't build up and/or run. I let it dry a couple days and baked it at 12o degrees for 20 minutes. I lightly wet sanded until the raised letters and borders were clean, used polishing compound to finish it before using a little car wax. No clear this time. I think it came out much better and wish I would have done the name plate the same way. Lesson learned. The little bit of exposed brass around the switch hole is covered by the switch retaining ring. I hope this helps anyone else who tries to do this. Forget the model paint and clear and use the rattle cans.

I think it's safe to say I'm done with name and switch plates and will start on the reverse shifter and motor and countershaft box next.

That's it for now.