-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

- Forums

- THE PROJECTS AREA

- PROJECT OF THE DAY --- WHAT DID YOU DO IN YOUR SHOP TODAY?

- Project of the Day Mega-Thread Archives

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

2015 POTD Thread Archive

- Thread starter jumps4

- Start date

- Joined

- May 8, 2015

- Messages

- 27

- Joined

- Sep 26, 2013

- Messages

- 408

What is on the end opposite the head? How about a little more info, is this a new to you mill, a job moving it for somebody, etc?

Maybe its just the camera angle but that looks like a beefier than normal BP.

thanks, Brian

- Joined

- May 8, 2015

- Messages

- 27

Sorry. Yes new to me. The guy said it's a shaper attachment. I'm just getting started with machinery. Joined the forums to do research and learn. It's been in a barn for several years. Working on putting the head back on.. wow..

- Joined

- May 8, 2015

- Messages

- 27

- Joined

- Feb 1, 2015

- Messages

- 9,577

L have found that a propane torch does a great job. A quick pass over and the web will burn but the tree will not be hurt.Kludged this up yesterday to remove some of the webworm nests in our persimmon tree. It's the nicest looking tree we have, and I don't want it to get stripped bare like it did last year.

Long piece of conduit, bamboo pole, two rakes, and plenty of duct tape.

View attachment 104829

- Joined

- Feb 8, 2014

- Messages

- 106

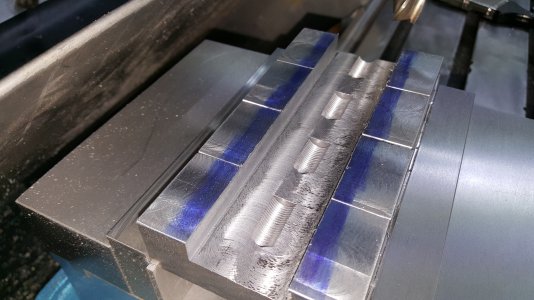

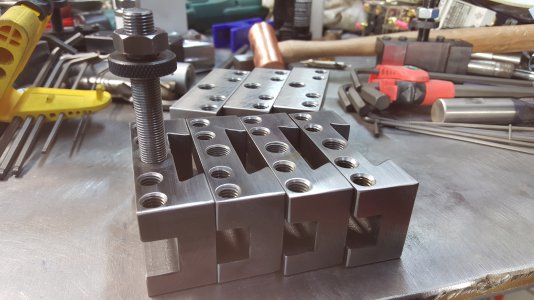

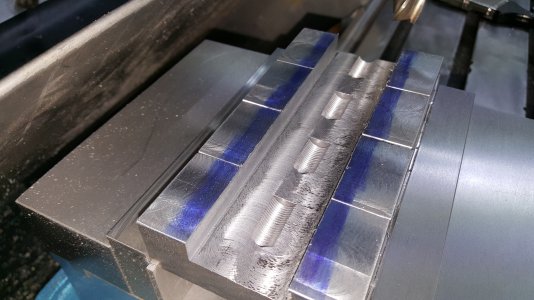

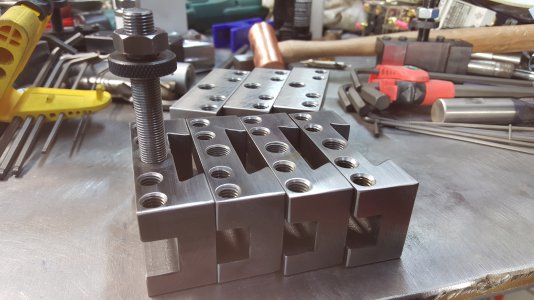

Well I resurrected the scrapped tool holders, cut the initial slot revealing the partial threaded trough, tig filled them and re-machined to proper depth and cut dovetail with my homemade insert cutter. Drilled and threaded the height adjustment post holes in the correct spot this time. My plan worked. Thanks again for all the input. 4 done - 3 to go tomorrow.

Actually it was really close - about .001" out front to back and .0015 left to right. I just re-trammed it using a new 13" brake rotor and was measuring/spinning the dial indicator 1/4" from the outside edge. It took me almost 1/2 an hour back and forth on the wrench to eliminate the differences. It now reads a perfect "0" at all angles!Jrstech, that finish your getting looks great, it appears to me that your Mills head is perfectly trammed.

- Joined

- Oct 5, 2010

- Messages

- 1,043

OK Andy, you officially suck ,

That is a hell of a find. I hope you didn't have to pay too much for it. With a little TLC you are going to have a great machine.

Randy

Note, in the machinist scrounger world, "suck" is a GOOD thing"

That is a hell of a find. I hope you didn't have to pay too much for it. With a little TLC you are going to have a great machine.

Randy

Note, in the machinist scrounger world, "suck" is a GOOD thing"

jrstech

Those look really good. I want some. I'm not sure my skills are up to that yet. But it is planned unless I ditch my tool holder for a different kid. There is another style I like better.

andy alford

That is a nice mill. That thing would probably make the hillside I live on slide. Lol

Those look really good. I want some. I'm not sure my skills are up to that yet. But it is planned unless I ditch my tool holder for a different kid. There is another style I like better.

andy alford

That is a nice mill. That thing would probably make the hillside I live on slide. Lol