- Joined

- Jul 4, 2014

- Messages

- 156

Guys,

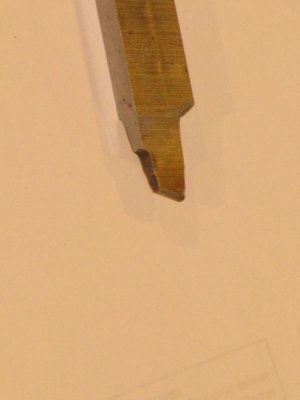

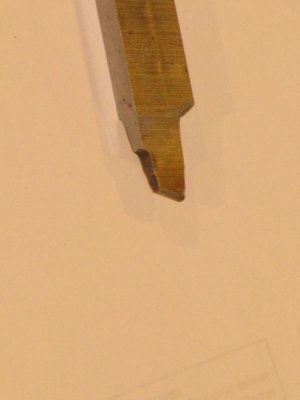

I was making a pulley out of aluminum stock. The pulley needs a round groove 5mm wide and 2.5mm deep with diameter at the bottom of the groove at 17 mm. I ground the round profile on a HSS tool bit. Cutting was not easy. I was getting very loud growling sound and heavy vibration. I tried many changes such as varying tool bit height, increase front clearance angle & side clearance angle, back rake and of course feed rate. Nothing resolved the problem. Finally I had to plunge the tool at extreme slow rate at all settings. I also used WD40. I am attaching photos of the tool tip I made.

Where did I go wrong?

What is the better/right way to do it?

Thanks

Prasad

Wynnewood PA

I was making a pulley out of aluminum stock. The pulley needs a round groove 5mm wide and 2.5mm deep with diameter at the bottom of the groove at 17 mm. I ground the round profile on a HSS tool bit. Cutting was not easy. I was getting very loud growling sound and heavy vibration. I tried many changes such as varying tool bit height, increase front clearance angle & side clearance angle, back rake and of course feed rate. Nothing resolved the problem. Finally I had to plunge the tool at extreme slow rate at all settings. I also used WD40. I am attaching photos of the tool tip I made.

Where did I go wrong?

What is the better/right way to do it?

Thanks

Prasad

Wynnewood PA