It must be 10 years since my neighbor and good friend gave me an antique lathe that has been his fathers. Here's what it looked like when he dragged it over to my barn:

It needed a motor, so I never tried to run it. And the belts looked pretty scary anyway. So of course the first thing I did was take it all apart to clean off many years of dirt and grease sitting in his barn, unused, and paint it. Time passes, and each time I got stuck on one particular section, I'd leave it (for years at a time) and move on to some other project. But now I'm determined to figure this thing out.

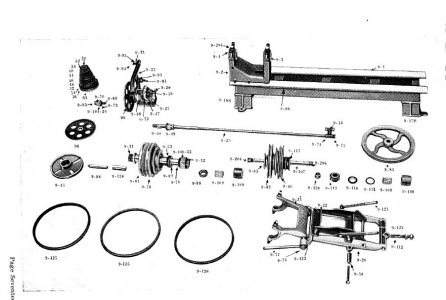

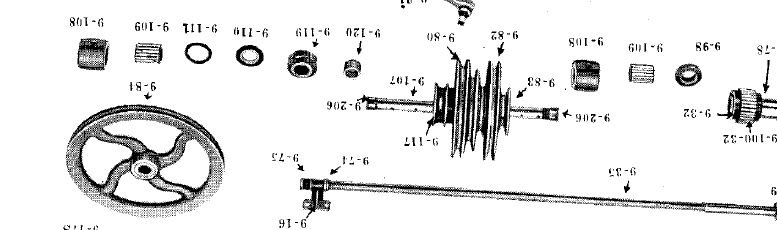

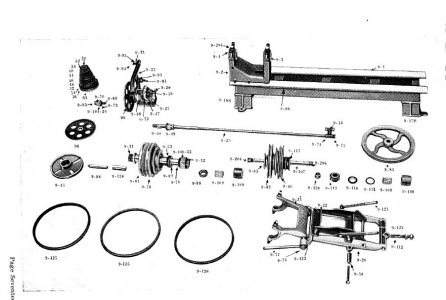

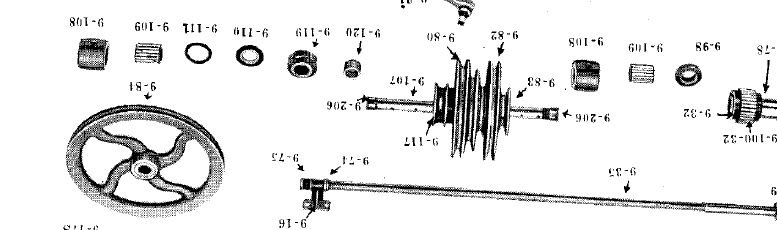

What I've been struggling with is assembling the top pulley spindle. I found a blow-up in a manual I found on-line, and after some frustration finally realized it was upside-down.

So it should look like this

So I've finally got it together and installed into the carrier, but I have a number of questions:

Question 1: on the top pulley spindle, should the 3-step cone pulley, and the large single pulley to it's left, be able to slide 1/4 inch, or should they be fixed laterally? I realize the shift collar is supposed to move to engage or disengage the large pulley next to the cone, but everything seems too loose on that spindle, between the bearings.

Which brings me to the next question. I'm wondering if I need to adjust the position of the clutch collar. I don't recall if I originally loosened and move this, ten years ago.

Question 2: a long shot, but can anyone give me a measurement on the location of this collar: (The picture is upside down because I initially thought it should point the other way)

Those seem to be the key issues right now.

Question 3: Finally, the belts. When I received the lathe, the original belts were on it. Each was stamped with the original part numbers: 9-125, 9-126. I read the lathe was built in 1933, so that makes them 80 yrs old, and they were pretty frayed. So, I had a local shop match them up, and they gave me A28 and A29 belts. But the two smaller belts are very tight, and the larger too loose. Can anyone help me with replacement sizes?

Question 4: while I'm at it, I've not found anywhere that can explain how the belt set-up is used. Why are there 3 belts anyway?

Any help that can be provided me would be greatly appreciated!

Paul

It needed a motor, so I never tried to run it. And the belts looked pretty scary anyway. So of course the first thing I did was take it all apart to clean off many years of dirt and grease sitting in his barn, unused, and paint it. Time passes, and each time I got stuck on one particular section, I'd leave it (for years at a time) and move on to some other project. But now I'm determined to figure this thing out.

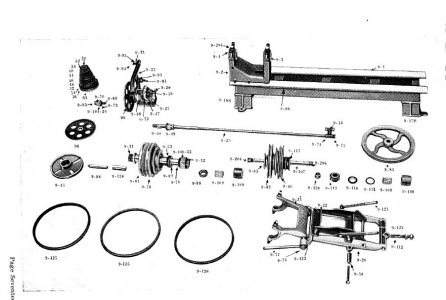

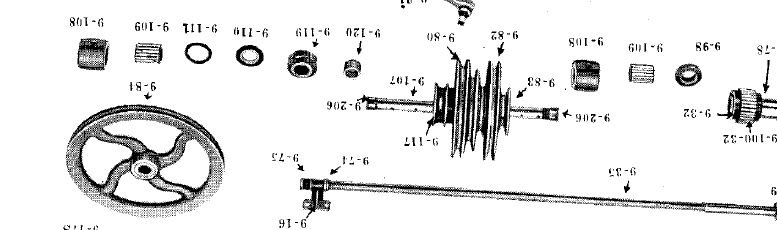

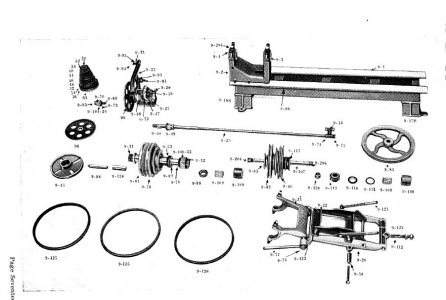

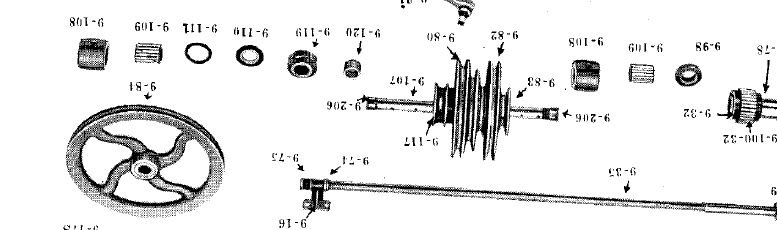

What I've been struggling with is assembling the top pulley spindle. I found a blow-up in a manual I found on-line, and after some frustration finally realized it was upside-down.

So it should look like this

So I've finally got it together and installed into the carrier, but I have a number of questions:

Question 1: on the top pulley spindle, should the 3-step cone pulley, and the large single pulley to it's left, be able to slide 1/4 inch, or should they be fixed laterally? I realize the shift collar is supposed to move to engage or disengage the large pulley next to the cone, but everything seems too loose on that spindle, between the bearings.

Which brings me to the next question. I'm wondering if I need to adjust the position of the clutch collar. I don't recall if I originally loosened and move this, ten years ago.

Question 2: a long shot, but can anyone give me a measurement on the location of this collar: (The picture is upside down because I initially thought it should point the other way)

Those seem to be the key issues right now.

Question 3: Finally, the belts. When I received the lathe, the original belts were on it. Each was stamped with the original part numbers: 9-125, 9-126. I read the lathe was built in 1933, so that makes them 80 yrs old, and they were pretty frayed. So, I had a local shop match them up, and they gave me A28 and A29 belts. But the two smaller belts are very tight, and the larger too loose. Can anyone help me with replacement sizes?

Question 4: while I'm at it, I've not found anywhere that can explain how the belt set-up is used. Why are there 3 belts anyway?

Any help that can be provided me would be greatly appreciated!

Paul