-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Cromwell S800 Mk3 lathe

- Thread starter RodF

- Start date

- Joined

- Apr 16, 2014

- Messages

- 142

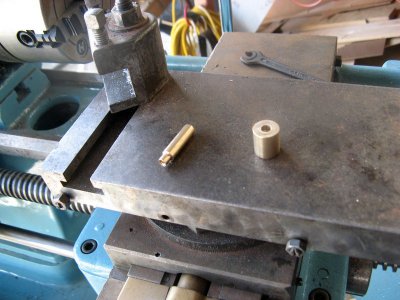

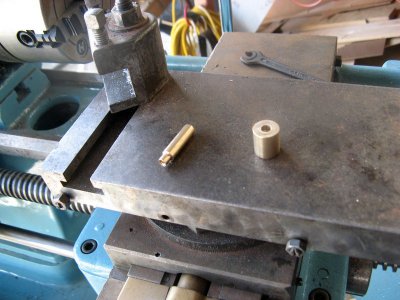

Made a pin and a retaining socket for the gearbox change arm. Not sure how close to the original design it is. Had to get a 3/8" BSF intermediate and bottom tap for the retainer from Tracy tools in the UK (they are great). Now I need to find or make a spring for it, needs to be 6mm or 7/64" diameter. Got the plate on too finally used those U screws. Really need to clean up the knurling on that knob and get it chromed.

Last edited:

- Joined

- Apr 16, 2014

- Messages

- 142

Cut the gears today. Just need to broach the key ways. Next up 40 tooth gear. The only problem is that I need a 45 or 9 hole indexing plate for the 90:1 rotary table to cut the 40 tooth gear. I am also wanting to cut a 76 tooth gear for another project so I need a 38 hole index as well. Fortunately I can use the indexing plates I have to make the new plate.

- Joined

- Apr 16, 2014

- Messages

- 142

- Joined

- Apr 16, 2014

- Messages

- 142