Cal,

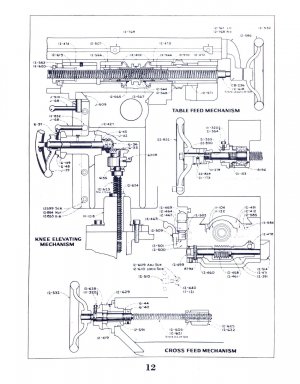

Thank you for the drawing. Helpful for a number of reasons, as my unit is missing the left hand table feed handle and accompanying items. Makes it interesting when trying to advance a known distance. My right side is a kluge as well, but at least has a crank.

I seem to recall there being tapped holes in the slot, near the ends. I have an adjustable t-bolt, but it just has a round tube on it. I get the idea from the drawings, and will try to figure a scale to get close to the actual size. Another opportunity to use the machine to make parts!

Speaking of which, in trying to get the feed gearbox cleaned up I managed to break the only semi-working shift lever (it was bent), so that I will need to make two shift levers. I did score a small 3-phase 1/4 HP, Frame 56 motor that looks like it will fit.

Working on making the peg end feather keys for the UHS head sliding gear, as well as the coupling links for the feed system. Breaking in my new rotary table, and have shown proof of concept to make the peg. Just need to schedule enough time to complete the chore. My machine is located miles away in the blacksmith shop at a museum, and try not to have the machine uncovered when there are fires going. Nasty coal smoke and grit.

Ron