- Joined

- Jan 23, 2015

- Messages

- 60

So Saturday and bringing home the big pieces can't come soon enough. Kinda like a kid waiting for Christmas. A lot of cleaning up of misc. parts done today and lots more to do. After Saturday I can tackle the table on which the lathe mounts. Its really grungy. Today was almost enough to make a grown man cry when I dumped some of the cardboard boxes of misc. stuff. Everything rusty. See photos. Lots of gears I'm guessing are surplus now with the quick change gear box for threading. Surprisingly the rust came off these fairly well. I didn't get to the two dozen or so taps except one 5/8x11 that turned out to be a Greenfield when rust and crud came off. The photo of all those laid out on my welding table should be titled "Table of Shame." It is beyond me that good tools just get chunked into moisture attracting cardboard boxes and left for months or years.

Lathe chuck is a Cushman 6. Was this standard on the 10" Logan/MW? It does have a set of outside (?) jaws that cleaned up pretty well considering they were coated in rust on every side earlier in the day.

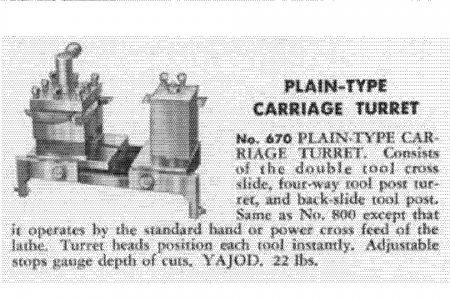

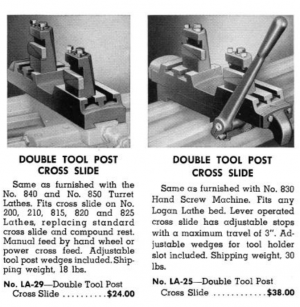

The custom tool holder that mounts in a T on the cross slide cleaned up nicely too and a 9-72 stamp was found on it. An interesting home made tool holder for a cut off tool was heavily coated in rust but cleaned up good also. It looks rough even cleaned up. I'm guessing on this too that it is meant to hold a cut off tool but I don't have a clue how it mounted. Any educated guesses?

Enough sharing for one night. I'm having a lot of fun and its keeping me busy while I'm waiting for the paint shop to get started on the 47 Olds convertible project.

Jerry

Lathe chuck is a Cushman 6. Was this standard on the 10" Logan/MW? It does have a set of outside (?) jaws that cleaned up pretty well considering they were coated in rust on every side earlier in the day.

The custom tool holder that mounts in a T on the cross slide cleaned up nicely too and a 9-72 stamp was found on it. An interesting home made tool holder for a cut off tool was heavily coated in rust but cleaned up good also. It looks rough even cleaned up. I'm guessing on this too that it is meant to hold a cut off tool but I don't have a clue how it mounted. Any educated guesses?

Enough sharing for one night. I'm having a lot of fun and its keeping me busy while I'm waiting for the paint shop to get started on the 47 Olds convertible project.

Jerry