- Joined

- Jul 23, 2015

- Messages

- 17

Hi All:

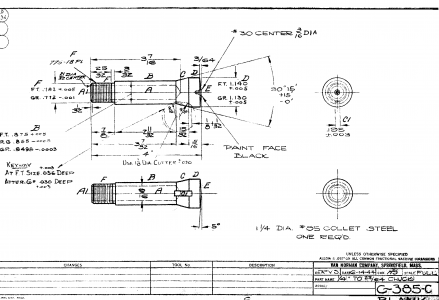

I've looked through several collet drawings on the web and in print but have not found what I am looking for. I'm interested in the radius of curvature on the nose of the collet. In other words I want to know the curvature of the surface that the cutting bit protrudes from. The VN collets I have look like they have a spherical front surface, but my Hardinge collets have a somewhat flatter and more conical front surface.

Normally, we only care about the taper and dimensions on the back side of the collet, but I am trying to measure and accurately draw a diagram of the collet retaining cap for the High Speed Quill Head. (See the photos in that thread for a picture of the threaded cap.)

The surface on the inside of the cap that touches the collet and pushes it back into the taper is machined with a slightly concave spherical surface to match the front face of the collet. It's a pretty difficult thing to try measuring accurately enough to get a decent idea of the radius of curvature. I'll be taking it in the work to see if our very accurate depth gauge can get to that machined surface and give me a profile.

But if I knew the radius on the front of my collets at least I would know approximately what that surface looked like. If anyone can point me to a drawing that would be great.

Thanks... Jeff

I've looked through several collet drawings on the web and in print but have not found what I am looking for. I'm interested in the radius of curvature on the nose of the collet. In other words I want to know the curvature of the surface that the cutting bit protrudes from. The VN collets I have look like they have a spherical front surface, but my Hardinge collets have a somewhat flatter and more conical front surface.

Normally, we only care about the taper and dimensions on the back side of the collet, but I am trying to measure and accurately draw a diagram of the collet retaining cap for the High Speed Quill Head. (See the photos in that thread for a picture of the threaded cap.)

The surface on the inside of the cap that touches the collet and pushes it back into the taper is machined with a slightly concave spherical surface to match the front face of the collet. It's a pretty difficult thing to try measuring accurately enough to get a decent idea of the radius of curvature. I'll be taking it in the work to see if our very accurate depth gauge can get to that machined surface and give me a profile.

But if I knew the radius on the front of my collets at least I would know approximately what that surface looked like. If anyone can point me to a drawing that would be great.

Thanks... Jeff