- Joined

- Feb 24, 2015

- Messages

- 1,382

Hey Franko- what if you simply splayed the legs out further? If they are angled 30* included angle, maybe cut and reweld the associated brackets to 40* or so? Seems that simply welding an offset in the legs themselves would lessen the hoist's capacity.

I agree, splay them legs

Isn't your hoist a 2 ton? I lifted my 1 ton mill with just the boom extended cause the legs wouldn't go around the pallet it was on, should have no problems hoisting a baby mill.

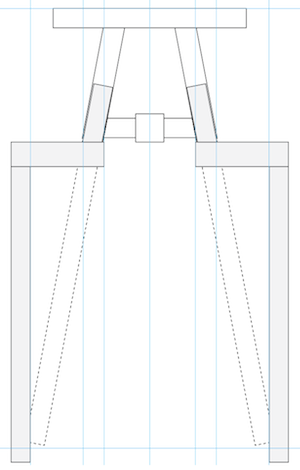

If I splay them it will shorten them. I'll have to cut and re-weld them. I was thinking of putting a Z bend in them so they would be parallel about 32" or wider apart. They'd still fold up for storage, could be rolled through a door while folded, and it would be a more useful tool. The thing has been not wide enough for everything I've used it for.

The complicating issue is that it's made with metric tube. Expensive around here. I could make the middle section of the Z with a close size of inch tube and cut the other two from the existing legs without losing any length.

Ken, I could have cribbed them up above the extended mill foot brackets. I thought of it, but was able to accomplish the task by ooching it onto the stand one foot at a time, though it felt dangerous. My hoist is a one-ton.