- Joined

- Mar 5, 2014

- Messages

- 381

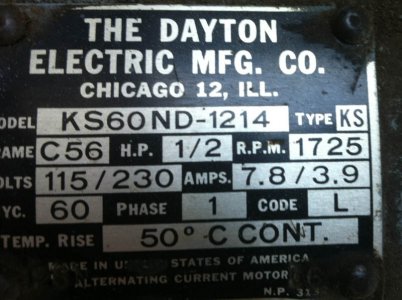

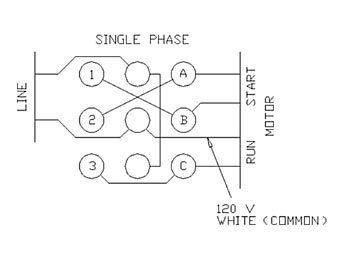

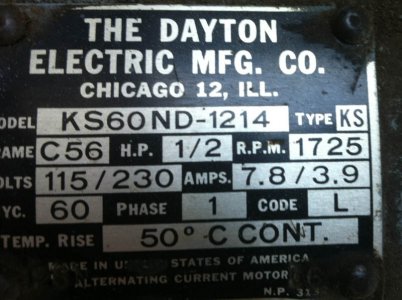

I just got my Logan 10 out of storage and noticed that the wires have become too brittle to use. The motor has gotten splashed with a little oil and coolant over the years and the markings are now obscured or non existent.

I need to label the Cutler Hamer Drum switch terminals so I can re-wire it properly. After I label the drum switch, I may need to post a photo of the labeled switch for help reverse engineering the wiring If the motor wires are not marked.

The power supply cord to the switch is Black/Red/Green

The two cords going from the switch to the motor are Black/Red/White/green and Black/White

D is Neutral

E is Hot/L1

A and F are jumpered

I would appreciate any wisdom you have.

John

I need to label the Cutler Hamer Drum switch terminals so I can re-wire it properly. After I label the drum switch, I may need to post a photo of the labeled switch for help reverse engineering the wiring If the motor wires are not marked.

The power supply cord to the switch is Black/Red/Green

The two cords going from the switch to the motor are Black/Red/White/green and Black/White

D is Neutral

E is Hot/L1

A and F are jumpered

I would appreciate any wisdom you have.

John