0

09kevin

Forum Guest

Register Today

Finally got round to making a fix for my old bandsaw (inherited it from a friend). It needed a new part so...

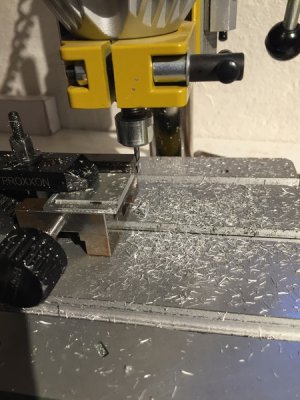

This was the most challenging part for me:

As the slot is only 1mm wide and the peice of alu is 6 mm, and i only had one 1mm mill.

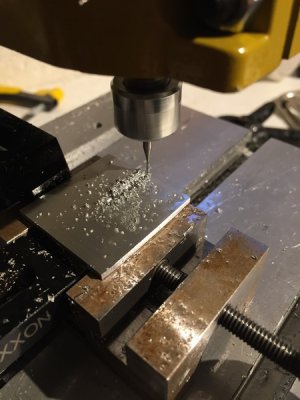

But pretty happy with the result:

I could have bought myself a new part, but it would have been plastic and probly break again.

Anyway all it cost me was time and the payback was a bit more machine experience for me.I am now much more confident with my little machine tool than when I started.

Leif

Sent from my iPhone using Tapatalk

So i made an air line addaptor, it's for a badger brand, the thread is some weird imperial / metric merger of weirdness. It's an M5 0.5 if i work it out in inches it came to 50tpi my leblond skipps that one so i cut it 52 tpi, works nicely, darn u badger airbrush co

So i made an air line addaptor, it's for a badger brand, the thread is some weird imperial / metric merger of weirdness. It's an M5 0.5 if i work it out in inches it came to 50tpi my leblond skipps that one so i cut it 52 tpi, works nicely, darn u badger airbrush co I recently moved and I have been setting up my shops, notice I said shops. 1 half of my basement is for the wood shop, and the other side is for the metal work side and a wall separates them. The wood shop now has 2 dust collectors, a stationary cyclone and a portable unit. It is going to be nice to have both separated now so I can do either craft. I was a wood worker first and that will always be my first love, but I do love to work metal as well and the tool collection for that is growing slowly as I learn. It is nice to be able to make tools and parts out of metal when the need arises.Thanks for the comments guys. The cabinet shop gives a nice break from the oil and grinding dust in the metal shop. I finally have separate spaces for the two, they don't mix. I could deal with shavings in the metal shop, but welding and grinding would leave the usual black dust on lumber that was like a permanent marker.

Greg

Looks like a nice setup pepi. I like the welder in the background of the last picture.