- Joined

- Dec 31, 2010

- Messages

- 937

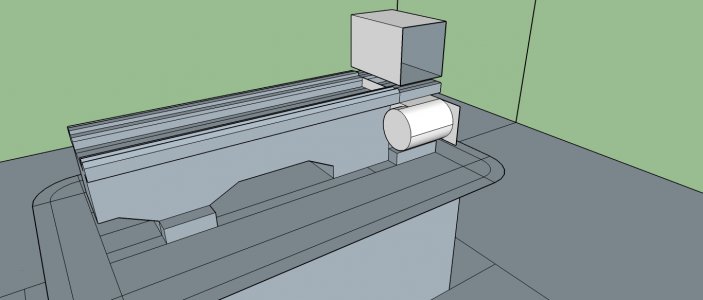

I go along with the comments previously made about the machine. Brino has a good point in checking it out to be sure it turns properly in all gear and belt positions.. After a little cleaning fire it up and see how it works.

I haven't noticed any comments lately about what type of material to learn how to make your first cuts but I would recommend schedule 40 plastic water pipe. It will "give" before any serious damage can be done to the machine.

If you are interested in books about machine shop work I like the text "Machine Shop Operations and Setups", the 4th edition has a good section on lathes. You may hear about many other publications as well.

I would be interested to know if that is a threading dial on the left side of the apron? If it is, 3it is the first time I have seen a set up like that.

Have a good day

Ray

I haven't noticed any comments lately about what type of material to learn how to make your first cuts but I would recommend schedule 40 plastic water pipe. It will "give" before any serious damage can be done to the machine.

If you are interested in books about machine shop work I like the text "Machine Shop Operations and Setups", the 4th edition has a good section on lathes. You may hear about many other publications as well.

I would be interested to know if that is a threading dial on the left side of the apron? If it is, 3it is the first time I have seen a set up like that.

Have a good day

Ray