- Joined

- Dec 2, 2012

- Messages

- 1,721

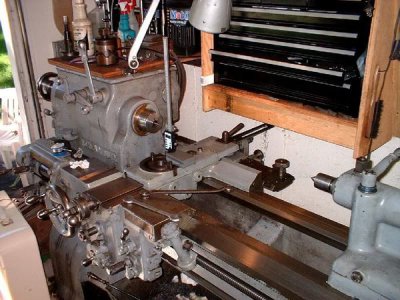

Oil cups are long gone and someone has lost the manual lol.

I have been putting iso oil in every hole I can find in this lathe, some are just bolts but they got oiled to lol.

I think the manual is on archive.org , when i got my baby 13 inch leblond I did a lot of searching for manuals for them.

Stuart

I could only find the dual drive manual their, i'm sure they had more , hummm (i just had a look)

I found this one, close but not quite , http://www.lostcreekmachine.com/PDF/runningaregal.pdf

Last edited: