- Joined

- Aug 12, 2014

- Messages

- 87

Hi All

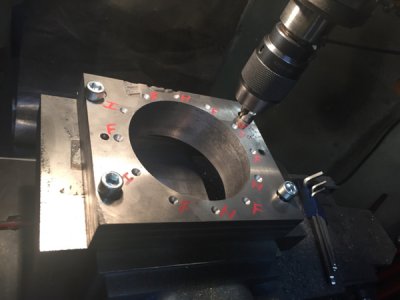

I have been working on and off building a new vertical spindle for my Tom Senior M1 Milling Machine. She is a old english machine dating from the late 50s. The current knucklehead vertical spindle i have has a set of helical gears that has seen better days. I wish to preserve the old knucklehead but having the gears cut will cost more than what another newer mill will cost. The Tom Senior is for it size class much more rigid than anything on the market and i really would love to keep on using it.

So i have started to build another vertical spindle to replace the knuckle head about a year ago. The spindle was made from EN19T , fairly tough stuff , especially on the old Myford ML7 i used to own.

I completed the spindle, bought the matched pair of angular contact bearings and deepgroove bearings for the floating part.

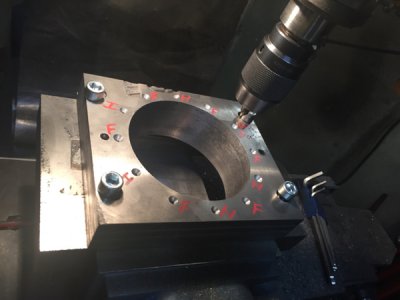

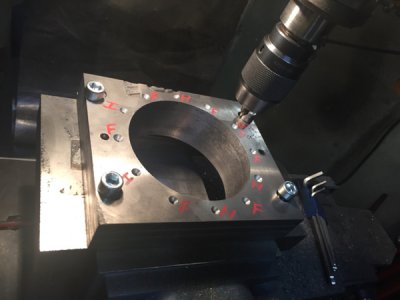

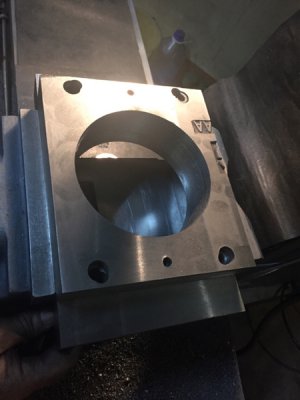

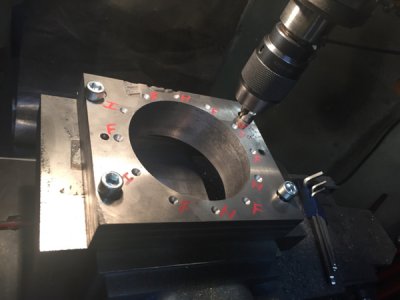

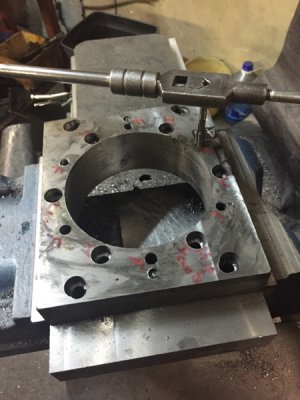

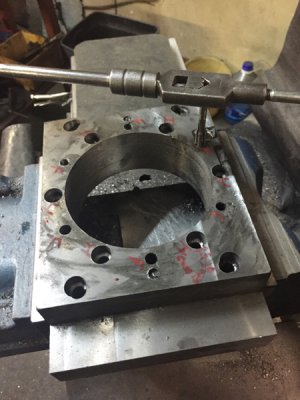

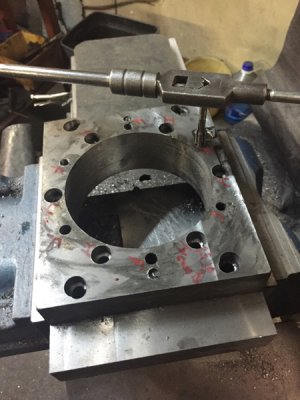

I started work on the quill and got hold of a cast iron "air operated vibrator"that has seized. i pressed the piston out and found that the bore was still in good condition. That would have been the housing for the whole assembly.

I have been working on and off building a new vertical spindle for my Tom Senior M1 Milling Machine. She is a old english machine dating from the late 50s. The current knucklehead vertical spindle i have has a set of helical gears that has seen better days. I wish to preserve the old knucklehead but having the gears cut will cost more than what another newer mill will cost. The Tom Senior is for it size class much more rigid than anything on the market and i really would love to keep on using it.

So i have started to build another vertical spindle to replace the knuckle head about a year ago. The spindle was made from EN19T , fairly tough stuff , especially on the old Myford ML7 i used to own.

I completed the spindle, bought the matched pair of angular contact bearings and deepgroove bearings for the floating part.

I started work on the quill and got hold of a cast iron "air operated vibrator"that has seized. i pressed the piston out and found that the bore was still in good condition. That would have been the housing for the whole assembly.

Last edited: