- Joined

- Sep 19, 2012

- Messages

- 3,063

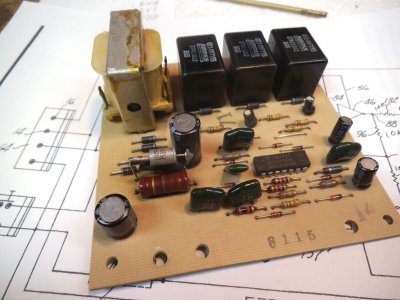

I finally got to install my single phaze breaker box.

The 3 phaze box had only 18 spaces, and I was running out of room fast! So I added a 24 space single phaze box with some 2" risers into a " bend box" for ez of pulling circuits.

The top box was a garbage can save from a demolished house! It leads onto a 6"x2" chanell iron "conduit that runs the entire perimeter of the shop. As I install the wall boards I will fish each circuit down to its terminal via 1" conduits.

By this time next year I might be making some swarf! LOL!

Sent from somewhere in East Texas Jake Parker

The 3 phaze box had only 18 spaces, and I was running out of room fast! So I added a 24 space single phaze box with some 2" risers into a " bend box" for ez of pulling circuits.

The top box was a garbage can save from a demolished house! It leads onto a 6"x2" chanell iron "conduit that runs the entire perimeter of the shop. As I install the wall boards I will fish each circuit down to its terminal via 1" conduits.

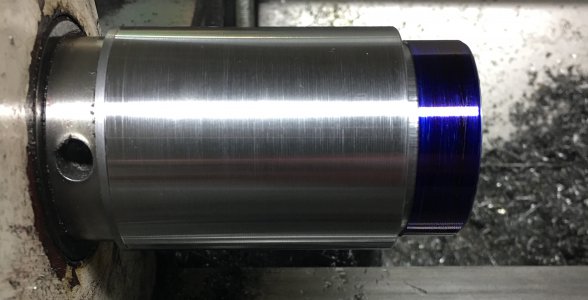

By this time next year I might be making some swarf! LOL!

Sent from somewhere in East Texas Jake Parker