-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Tom Senior / Maho Vertical Mill Spindle Mod

- Thread starter rhynardt

- Start date

- Joined

- Aug 12, 2014

- Messages

- 87

- Joined

- Sep 28, 2013

- Messages

- 4,305

dang, that's some impressive fabrication work!

- Joined

- Apr 28, 2014

- Messages

- 3,590

Now if I grabbed a scrap counter and machined it, about halfway through I'd hit a void that was filled with sand and that's when

things would really start getting interesting...

things would really start getting interesting...

- Joined

- Aug 12, 2014

- Messages

- 87

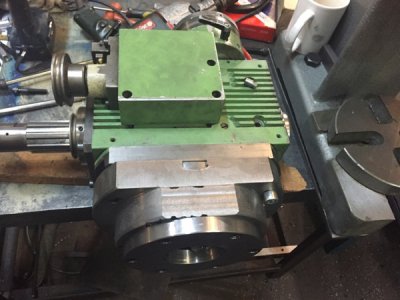

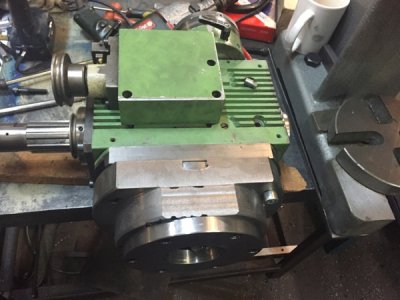

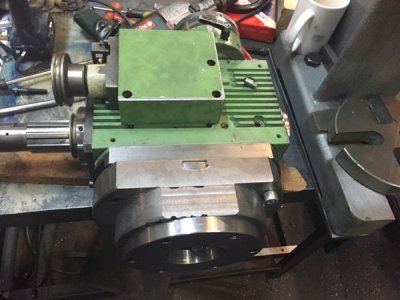

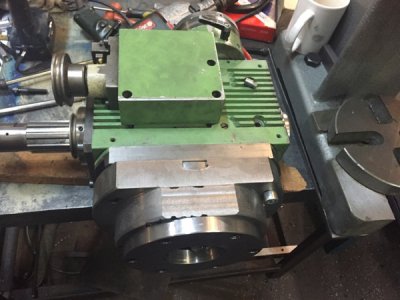

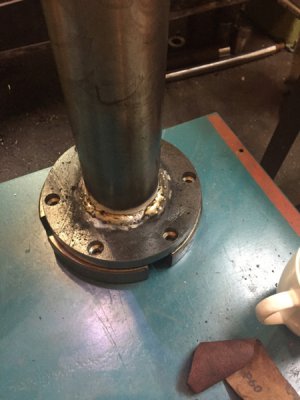

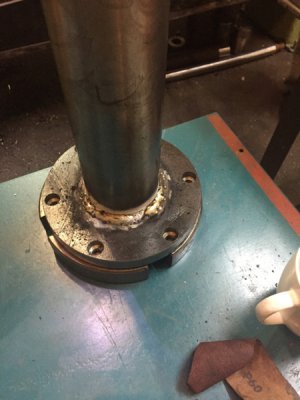

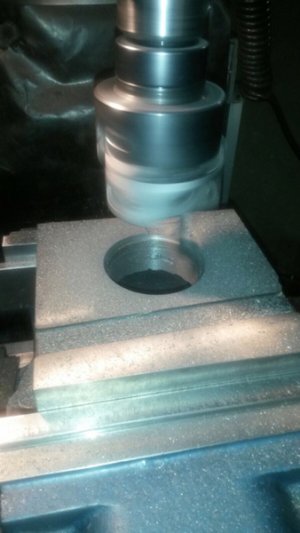

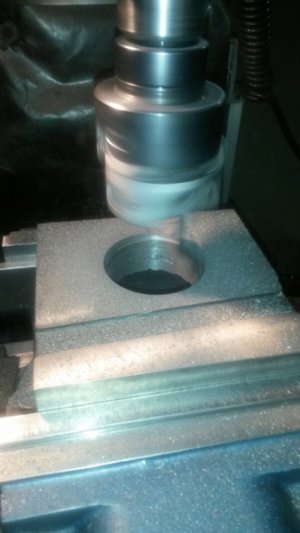

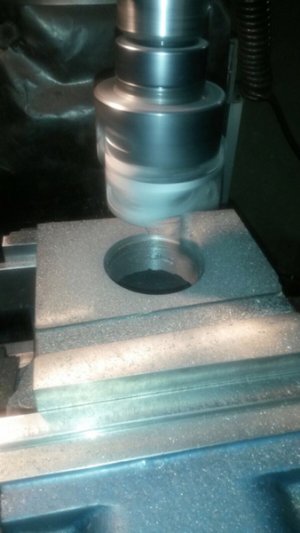

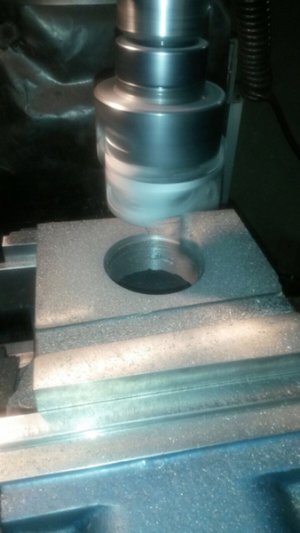

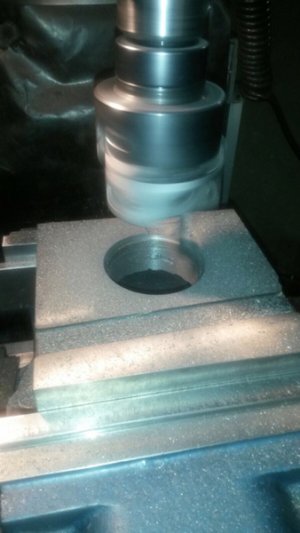

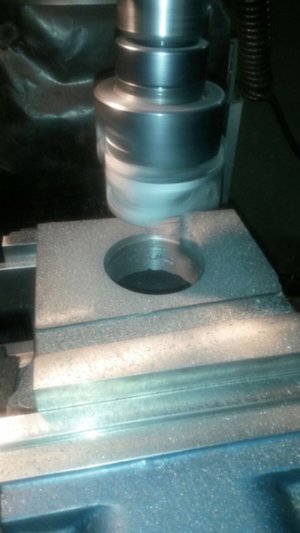

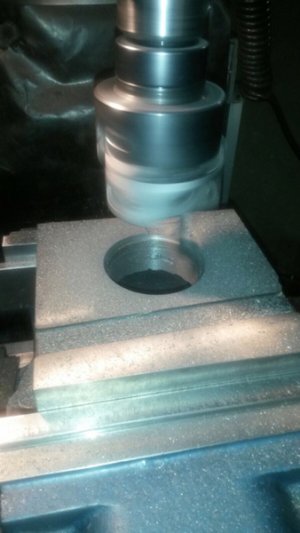

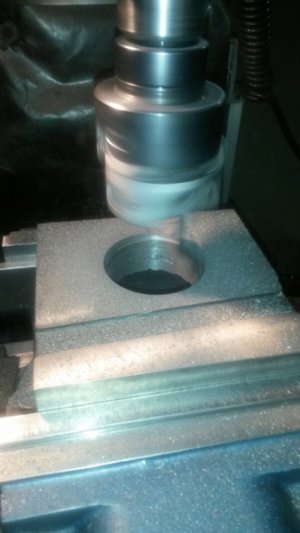

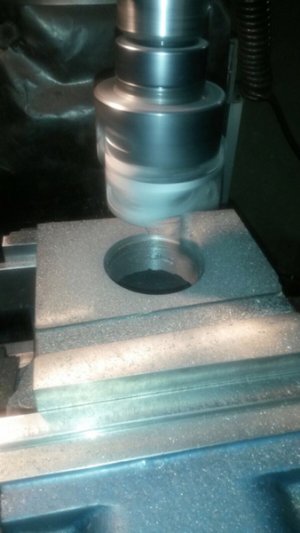

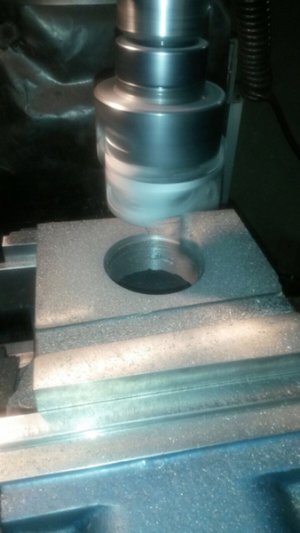

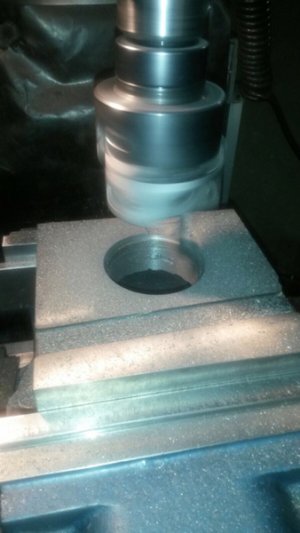

I was quite astounded by the quality of the cast iron, not a single void in sight! Got a bit further this morning. Cleaned up the welded flange and trued up any warpage from the welding heat. Also bored the two pockets for the driveshaft bearings.

Did a testfit with the head assembly and it all looks good!

Things are going to slow down a bit now as we are moving cross border for a month to have my daughter born. Hopefully we can come back sooner and i can finish off this project

Did a testfit with the head assembly and it all looks good!

Things are going to slow down a bit now as we are moving cross border for a month to have my daughter born. Hopefully we can come back sooner and i can finish off this project

Last edited:

- Joined

- Aug 12, 2014

- Messages

- 87

Hi All

Got back home earlier today with a beautifull noisy 2week old babygirl. Guess i should start looking for a shotgun....

Getting back to the Tom Senior-Maho marriage...

A fellow machinist friend decided to give me a surprise and complete the driveshaft and pillowblocks, ready to mount on the machine!

Herewith a couple of pics he took for me

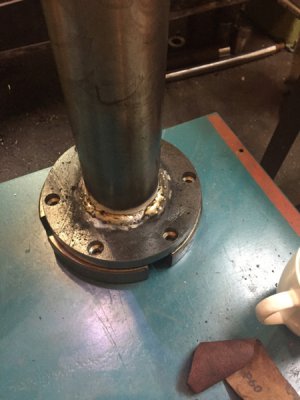

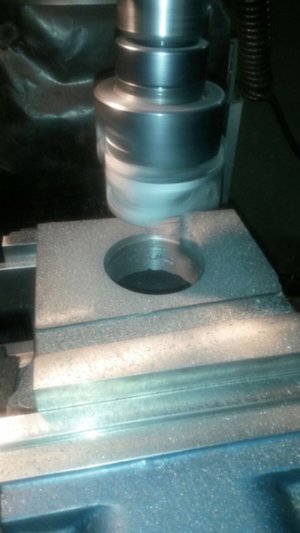

Making of the driveshaft:

Next op the boring of the pillowblocks and the completed project:

Tomorrow morning i will go and fetch it and attempt to mount it. Once that is done i will have to figure out exactly how i will transfer drive to the head. I have a 1,2kw -3 phase motor and vfd already waiting for this job.

Will take plenty more pics tomorrow when setting up

Got back home earlier today with a beautifull noisy 2week old babygirl. Guess i should start looking for a shotgun....

Getting back to the Tom Senior-Maho marriage...

A fellow machinist friend decided to give me a surprise and complete the driveshaft and pillowblocks, ready to mount on the machine!

Herewith a couple of pics he took for me

Making of the driveshaft:

Next op the boring of the pillowblocks and the completed project:

Tomorrow morning i will go and fetch it and attempt to mount it. Once that is done i will have to figure out exactly how i will transfer drive to the head. I have a 1,2kw -3 phase motor and vfd already waiting for this job.

Will take plenty more pics tomorrow when setting up

- Joined

- Aug 12, 2014

- Messages

- 87

Hi All

Got my Maho milling head mounted!!!

After endless power outages today in this brutal heat we are currently experiencing i threw in the towel as my workshop is like a oven when the ac doesnt run! So i got it mounted and left it there.

I lifted the whole assembly to see how it all fits on the mill body with a engine jack with a rope through the spindle

I then proceded to measure out the mounting holes for the pillowblocks, lay it out on the mill body and drilled the 12mm holes for the allencap bolts. Once that was done i bolted them on lightly so i could bed the horisontal arm straight and in line

Then i bedded the horisontal arm in the pillowblocks, tapped everything straight with my mallet and she seated very well!

Then i fastened the top of the pillowblocks to the bottoms and started to tighten all the bolts holding the assembly to the mill body

It looks like the business!!

Hopefully the power wants to remain stable tomorrow so i can get some work done

Got my Maho milling head mounted!!!

After endless power outages today in this brutal heat we are currently experiencing i threw in the towel as my workshop is like a oven when the ac doesnt run! So i got it mounted and left it there.

I lifted the whole assembly to see how it all fits on the mill body with a engine jack with a rope through the spindle

I then proceded to measure out the mounting holes for the pillowblocks, lay it out on the mill body and drilled the 12mm holes for the allencap bolts. Once that was done i bolted them on lightly so i could bed the horisontal arm straight and in line

Then i bedded the horisontal arm in the pillowblocks, tapped everything straight with my mallet and she seated very well!

Then i fastened the top of the pillowblocks to the bottoms and started to tighten all the bolts holding the assembly to the mill body

It looks like the business!!

Hopefully the power wants to remain stable tomorrow so i can get some work done

G

Grumpy Gator

Forum Guest

Register Today

First congratulation's on your new baby girl.

Excellent modification very well documented.

We had a Senior M1 in the shop. Very stout machine.When my uncle / teacher passed he left me all the machines in the shop. Unfortunately the estate was in probate for 18 months so she doesn't look her best.

Here is a picture of her {We called her Gertie}

Keep up the good work. Looking forward to seeing her completed.

*G*

Excellent modification very well documented.

We had a Senior M1 in the shop. Very stout machine.When my uncle / teacher passed he left me all the machines in the shop. Unfortunately the estate was in probate for 18 months so she doesn't look her best.

Here is a picture of her {We called her Gertie}

TomseniorM-1003

- Deleted member 18150

- 1

*G*