- Joined

- Oct 6, 2010

- Messages

- 699

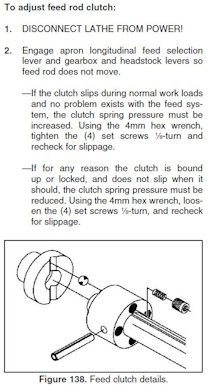

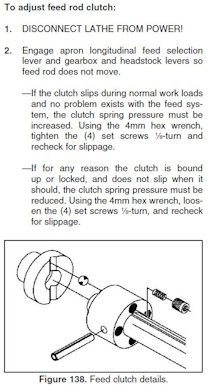

My unplanned project lathe came with a ball detent clutch that was not mentioned or shown in the manual. I have looked at a number of Jet Lathe manuals and have not found one that provides definitive information for this type clutch adjustment. The newer model Jet lathe uses a slip clutch but that manual did not provide much help on how to adjust it either. I did find a Grizzly manual that gives instructions about their ball detent clutch as shown below:

Again, this does not seem like enough information to properly protect a lathe. I have no idea what the “normal work load” is. I would think the clutch should transmit enough torque to take a certain defined cut and not damage the lathe gear train. It would be nice if the required setting could be measured with a torque wrench applied to the feed rod side of the clutch. I don’t want to cause more damage learning to use the lathe once I get it operational!

Has anyone adjusted one of these clutches and how did you determine the setting?

Thanks in advance.

Benny

The Orphanage Never Closes

Again, this does not seem like enough information to properly protect a lathe. I have no idea what the “normal work load” is. I would think the clutch should transmit enough torque to take a certain defined cut and not damage the lathe gear train. It would be nice if the required setting could be measured with a torque wrench applied to the feed rod side of the clutch. I don’t want to cause more damage learning to use the lathe once I get it operational!

Has anyone adjusted one of these clutches and how did you determine the setting?

Thanks in advance.

Benny

The Orphanage Never Closes