- Joined

- Jan 25, 2015

- Messages

- 2,558

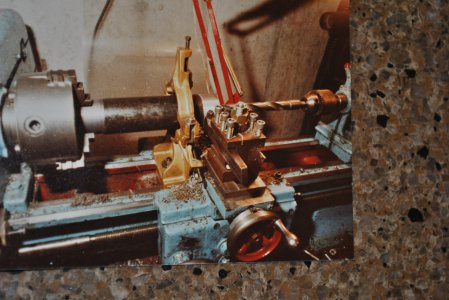

I have the same holder and parting blade. The problem is the holder is not made for that type of parting blade. The holder has no relief for the top portion of the blade that is wider than the body portion. What happens when you install the blade flush with the holder the blade is not held vertical and it is somewhat tilted to the side. What you need to do is mill a relief slot in the holder so the body portion of the blade can be mounted flush to the holder. Hope I'm making myself clear. I can take a picture of my holder in the morning and post it if that will help.

Tom S.

Yep, I understand. I have looked at that before. I haven't milled the slot yet, but maybe it's time to do so...