- Joined

- Jul 23, 2014

- Messages

- 347

Because they are basically made from tin and will melt?Remove the set screws FIRST!

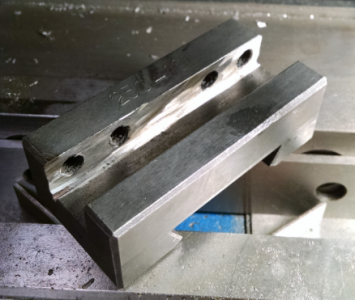

I have a .045" thick cut off wheel for my angle grinder so I should be able to get all the way to the corner, I can easy enough slice .06 off. Then it would just be cleanup with the EM. I'll give it a try and report back.