-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

101.07301 - Newb Needs Help

- Thread starter Csd1984

- Start date

Thanks! You guys are extremely helpful. I spent some time with the lathe today and cleaned all of those accessories with degreaser and rust remover. Then sprayed with oil liberally. I'll oil the machine liberally tomorrow. I bought a big can of WD40 and machine oil.

- Joined

- Dec 25, 2011

- Messages

- 10,510

I forgot to add one comment. Although the die grinder holder is a bit large for a 6", it is sometimes handy to be able to use a small die grinder or Dremel mounted to the tool post. Especially if you don't own one of the Atlas tool post grinders. For example, if you have to grind your chuck jaws. Or I once needed to be able to cut off some very small diameter stainless thin wall tubing (less than 1/8" dia.) and without leaving any bur on the ID. I made a holder for one of my Dremels and used a cutoff disk.

http://m.ebay.com/itm/Atlas-6638-Wo...l-Turning-Lathes-new-/182021228312?nav=SEARCH

Is this what I buy for this particular lathe for wood turning?

Is this what I buy for this particular lathe for wood turning?

- Joined

- Dec 12, 2011

- Messages

- 132

Seems like a ridiculous price when a piece of angle with a hole to fit your T-nut would work at least as well or better. Looks to me like that long mounting ear would always get in the way . You need room for your guiding hand. Also if you look at the pictures of how to use it they show a totally different rest. One last note is you want a hard smooth surface for the tool to ride on .http://m.ebay.com/itm/Atlas-6638-Wo...l-Turning-Lathes-new-/182021228312?nav=SEARCH

Is this what I buy for this particular lathe for wood turning?

WH

Last edited:

- Joined

- Sep 28, 2013

- Messages

- 4,305

hold up there for a moment csd - I think there's a real risk of you doing some damage until you understand some of your lathe's functions better. The lever you mentioned earlier is to change direction of rotation of the leadscrew - it makes more noise in the up or down positions because it's engaging the gear at the end of the spindle. Not a good idea to do it while the lathe is running and nor should you need to. There's another lever on the headstock - don't shift that one under power either! The manual for this lathe is easy to find, have a good read of that and How to Run a Lathe by Southbend first.

These are pretty forgiving machines (I rebuilt one recently so it can't be that hard) but you can rack up some pricey repairs very quickly if you don't know what you're doing and your posts suggest you're right at the beginning of your learning curve. Nothing wrong with that, we all started at that point, myself included, but no need to make all of our mistakes too!

These are pretty forgiving machines (I rebuilt one recently so it can't be that hard) but you can rack up some pricey repairs very quickly if you don't know what you're doing and your posts suggest you're right at the beginning of your learning curve. Nothing wrong with that, we all started at that point, myself included, but no need to make all of our mistakes too!

- Joined

- Dec 25, 2011

- Messages

- 10,510

http://m.ebay.com/itm/Atlas-6638-Wo...l-Turning-Lathes-new-/182021228312?nav=SEARCH

Is this what I buy for this particular lathe for wood turning?

Csd,

Yes, those two tool rests will attach to the T-slot in your compound rest to support the various wood turning tools. Several of the Figures do seem to show a different support. I suspect that instead of making new drawings from scratch for the 6638 instruction sheet, Clausing used some drawings from the manual for one of the actual wood turning lathes that Atlas once built. Or maybe from the instruction sheet for the M6-330 6" wood turning tool rest that they once built. Remember that when Atlas built the 6" metal turning lathes, they were primarily intended for metal turning. So there would be some compromises to use one for wood turning.

As there is generally no particular use for the capabilities of the compound slide and swivel, a better setup, still using the 6638, would be to remove the complete compound assembly from the cross slide and replace it with a round post of the same height that would attach to the pintle on the cross slide in the same manner as the compound swivel attaches. The top of the post would be drilled and tapped for the bolt that attaches the tool rests.

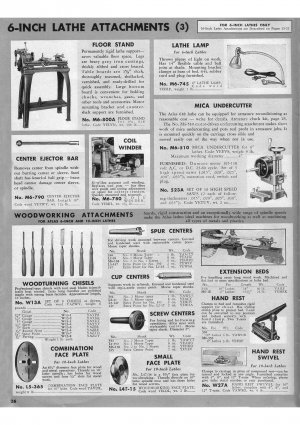

Shown below is a page from the Atlas 1945 general catalog. The photos are a bit better than those in the 1943 Sears catalog. Everything except items that screw onto the spindle nose will also fit your machine. The lower half of the page shows various wood turning accessories that Atlas once sold (why some 10" parts slipped in I don't know). Note that to use the M6-330 tool rest, you would remove the carriage. In order to do wood turning, besides a tool rest, you are going to need a few of the items shown, although they certainly don't have to have been originally made by Atlas. You will need a spur center for example. And probably a screw center. As these are only used in the spindle, they may as well be No. 2 Morse Taper. You already have a live center for the tailstock but you would probably be better off using the L2-17 (or equivalent) cup center. It won't tend to wallow out as much as just a plain dead or live center would. And you have a faceplate that presumably has 1"-8 threads (the Atlas 618 has 1"-10, so don't buy anything with that thread even if cheap and made by Atlas).