- Joined

- Dec 30, 2015

- Messages

- 131

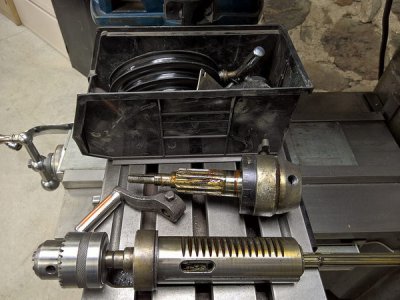

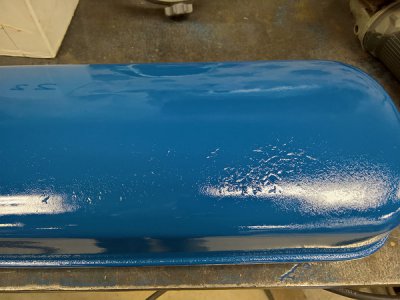

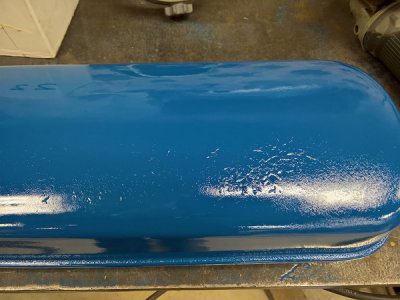

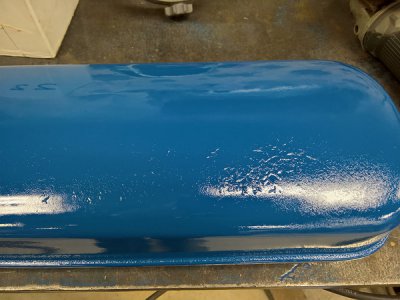

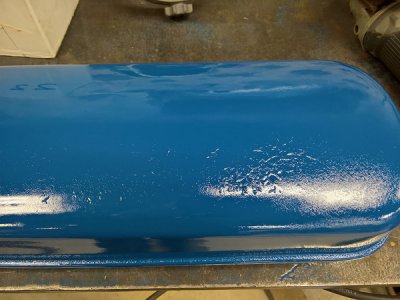

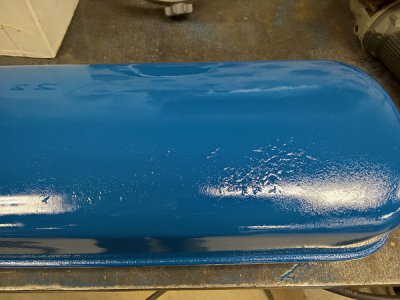

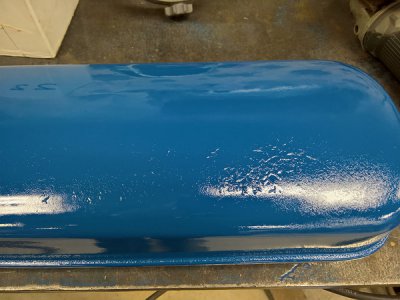

I've had this old drill press for a while now and while it did a reasonable job at some tasks, it didn't work for many that I needed to use it for. To start with, it looked like crap which isn't a big deal but since I have been on a restoration/rebuild kick lately, I thought that I would spruce it up a bit. Next is that it's a 3 shaft machine with step pulleys and it doesn't have the range of speeds that I needed and it is seriously lacking in power. Lastly, as a tool and die maker no longer doing that kind of work, I really missed having a tool room drill press with reversing switch for power tapping.

The first thing that I did with it was strip it down to nothing and clean or sand blast all of it. It's a cheap Taiwanese machine but not built too badly and is reasonably robust. Lots to be desired in overall quality but beggars can't be choosers. I also wanted to show the process of doing this so that if there are others that want to, they can follow my lead.

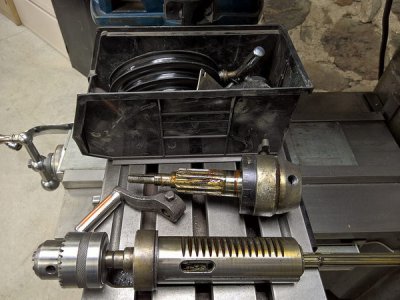

I removed all of the rivets using the TIG welder to put a blob on each one and pull them out with visegrips.

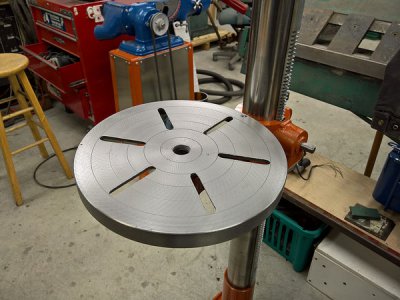

As the final piece to clean up was the post, I had to figure out how I was going to make it look good. I tried to remove the bottom flange but even with some heat, it wouldn't budge. I wasn't completely in need of removing it but thought that it would be better without it when spinning it in the lathe. So on it stayed.

The first thing that I did with it was strip it down to nothing and clean or sand blast all of it. It's a cheap Taiwanese machine but not built too badly and is reasonably robust. Lots to be desired in overall quality but beggars can't be choosers. I also wanted to show the process of doing this so that if there are others that want to, they can follow my lead.

I removed all of the rivets using the TIG welder to put a blob on each one and pull them out with visegrips.

As the final piece to clean up was the post, I had to figure out how I was going to make it look good. I tried to remove the bottom flange but even with some heat, it wouldn't budge. I wasn't completely in need of removing it but thought that it would be better without it when spinning it in the lathe. So on it stayed.