F

f350ca

Forum Guest

Register Today

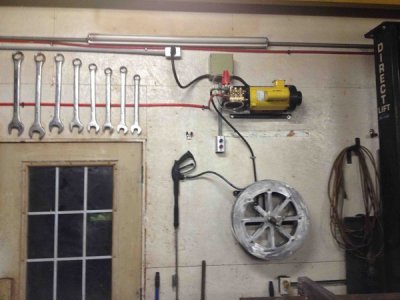

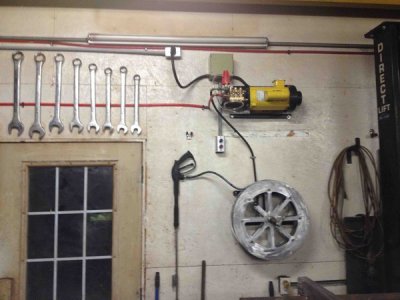

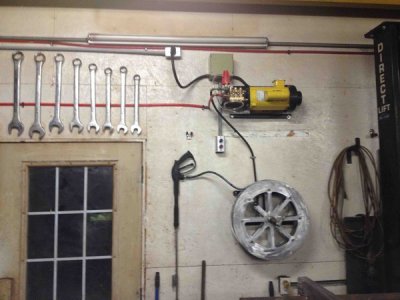

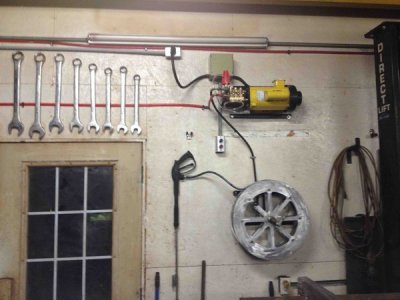

I need all the help I can get when it comes to keeping things clean. Was given a little portable electric pressure washer years ago. It only worked long enough to convince me the gas one was a pain, its never been started again. The one I have now is sufficient, but by the time I dig it out of the back of the shop, hook up the hose, find the wand plug it in drag it out side its usually easier to leave things dirty. Thats what happened the last time I had the atv's out. So I decided to have a permanently mounted one by the door. Started looking at pumps, some junk then looked at commercial ones, then industrial. In the end bought a made in Italy Comet brand triplex.

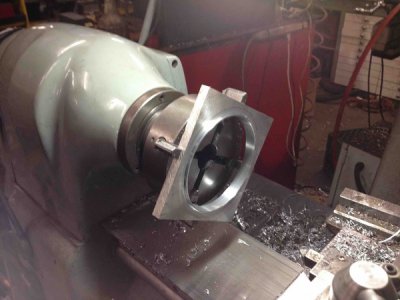

Had a pump from a jacuzzi that someone gave me. Its 220 volt and 15 amp on its high speed of 3400 rpm, so guessing around 3 hp, a little more than they recommended for the pump.

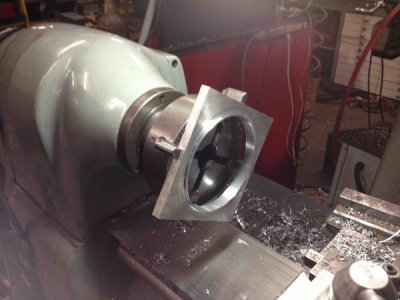

The shaft however was 1/2 inch with a 3/8 thread on the end. Built it up with the mig. (no pictures, it wasn't pretty), as usual the end warped so I used the steady rest on the bearing surface and re-centered the end.

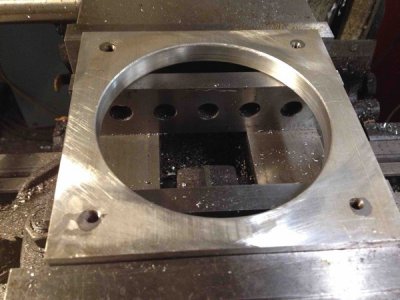

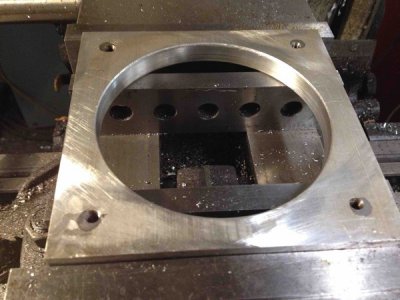

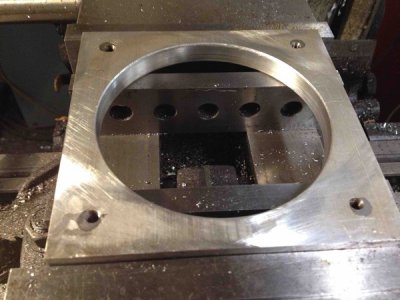

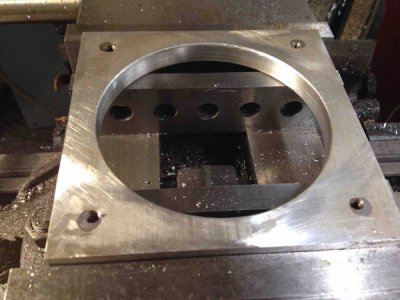

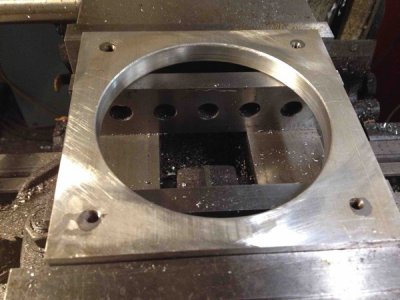

Turned it between centers or collet and centre to 5/8 to match the pump. Its now in the mill, ready for a keyway after coffee.

Greg

Had a pump from a jacuzzi that someone gave me. Its 220 volt and 15 amp on its high speed of 3400 rpm, so guessing around 3 hp, a little more than they recommended for the pump.

The shaft however was 1/2 inch with a 3/8 thread on the end. Built it up with the mig. (no pictures, it wasn't pretty), as usual the end warped so I used the steady rest on the bearing surface and re-centered the end.

Turned it between centers or collet and centre to 5/8 to match the pump. Its now in the mill, ready for a keyway after coffee.

Greg

I'm gonna have to remember that one.

I'm gonna have to remember that one.