-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

B

Bill Gruby

Forum Guest

Register Today

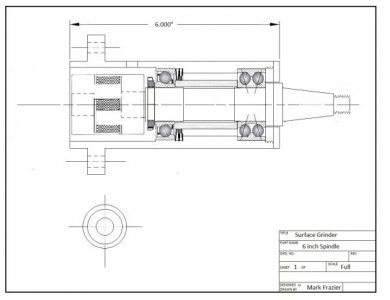

You may discuss this at will but, be assured we know they are wrong. A new print will straighten it out. I believe I pointed that out a few posts back right after you asked Bill. Post #256, last sentence. I have an extreme distaste for fault finding after it has already been found by us and stated as such. Mark and I do not claim to be experts, we make mistakes.

Last edited by a moderator:

I used a generic symbol for the bearing. It may appear wrong in the computer drawing but I mistakenly took for granted anyone using the bearing knew which direction to put it in. From now on I will use Very generic symbols so as not to confuse anyone. You are correct the drawing is wrong but that was the only symbol I had and we noticed it. ( I guess everyone else did too).

B

Bill Gruby

Forum Guest

Register Today

Once again, I, ME, MYSELF used generic bearing symbols to draw the print. These were the symbols I had. I mistakenly assumed anyone using a bearing would know how to put it in. Everyone got so hung up on the bearing symbols they didn't even notice the real problem. I had left the front cap that captures the assembly off the drawing. I revised it and posted I revised it and everyone was too busy flapping about a symbol to even notice. I, ME, MYSELF went back to the original drawing post and turned the symbol around. Billh50, you asked a question and that is fine. you are paying attention. You asked and was answered. I'm glad you are observant. As for the rest of the flap, If you have any smart comments about my print or me, make them in a PM. If you have a question, ask it here.The double row did not concern me too much as they are preloaded. I just wanted to make sure no one was putting the single one in backwards.

This spindle is not built yet and I , ME, chose the bearing symbols to be able to draw the print. the bearing numbers may change. they are not written in stone. Once the actual bearings are in my hand and I know they are what I will use, I WILL revise the print again.

- Joined

- Mar 19, 2014

- Messages

- 2,680

Your spindle design is very similar to a Levin ball bearing type headstock, for example. I have seen the matched angular contact bearings for the front. But in the back I typical see a standard deep groove bearing and not another angular contact bearing with a Belleville washer set-up. What I see is a deep groove bearing in the back that kinda floats and the matched angular in the front are held in fast at their OD race with a face plate. And the locking nut at the back of the spindle holds/secures all the parts onto the spindle. The nut in the back does not adjust preload, that is done with the matched pair of angular bearings.

Also my surface grinder has a felt seal at the front to prevent crap from getting to the bearings. It’s just a groove cut into the front of the spindle nose housing and a washer like piece of felt (not rubber) made to fit the groove and just rides the OD of the spindle…Dave.

Also my surface grinder has a felt seal at the front to prevent crap from getting to the bearings. It’s just a groove cut into the front of the spindle nose housing and a washer like piece of felt (not rubber) made to fit the groove and just rides the OD of the spindle…Dave.

Last edited:

Your spindle design is very similar to a Levin ball bearing type headstock, for example. I have seen the matched angular contact bearings for the front. But in the back I typical see a standard deep groove bearing and not another angular contact bearing with a Belleville washer set-up. What I see is a deep groove bearing in the back that kinda floats and the matched angular in the front are held in fast at their OD race with a face plate. And the locking nut at the back of the spindle holds/secures all the parts onto the spindle. The nut in the back does not adjust preload, that is done with the matched pair of angular bearings.

Also my surface grinder has a felt seal at the front to prevent crap from getting to the bearings. It’s just a groove cut into the front of the spindle nose housing and a washer like piece of felt (not rubber) made to fit the groove and just rides the OD of the spindle…Dave.

you are correct in what you say. There are many ways to build a spindle. This was mine and Bill's first choice. There may be changes to this spindle , but they will be minor. Such as the rear bearing, and I had thought about the felt seal and still may use it although it isn't really needed with the design I want to use. We shall see. Thank you for the information and thoughts.

O

ome

Forum Guest

Register Today

Sorry If I missed something, but how similar is this build to the small Sanford?

I own one with manual feed, and would be happy to post any pics.

I own one with manual feed, and would be happy to post any pics.

B

Bill Gruby

Forum Guest

Register Today

John,

I am not familiar with that machine so I am sorry I have no answer. Maybe someone else can. Keep watching.

"Bill"

I am not familiar with that machine so I am sorry I have no answer. Maybe someone else can. Keep watching.

"Bill"

- Joined

- Jan 26, 2015

- Messages

- 1,939

I do have to apologize if I started something. My only concern was that someone with either no or very little experience with bearings might put the bearing in wrong. Only because we do have many people who are new to this type of hobby. Next time I will keep my comments like that to PM's.