- Joined

- Jun 20, 2016

- Messages

- 346

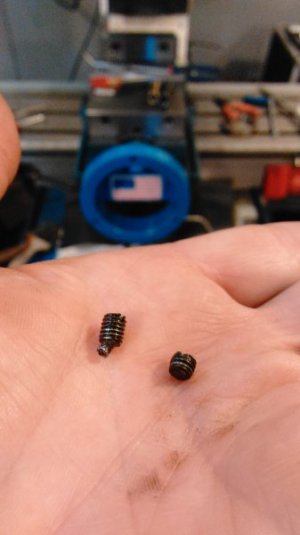

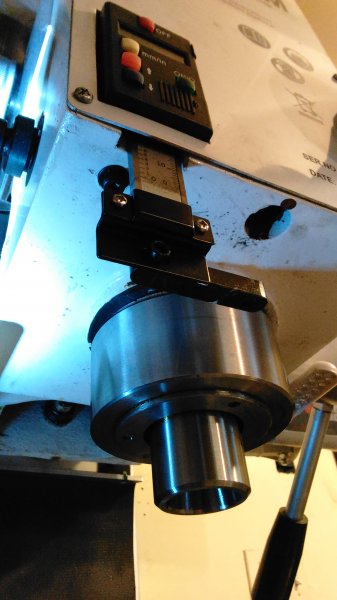

My collets have been rough going up in the spindle . I looked up in there and the little R8 aligning grub screw is a little bit galled over. I'd like to remove this grub screw but can't figure out how. I removed the quill base but see no way to get at the grub screw. I called Matt earlier this week from work on lunch break ...it sounded easy to get at .....Since i'm off today, i've been trying to get at it and cant figure out how.

Anyone know how to get this grub screw out of the spindle ?

Seems I need to lower the spindle out of the quill to do it ... I figure i'd ask

the PM community before I make a bigger job if i'm missing something simple.

Any help appreciated, Thanks !

Anyone know how to get this grub screw out of the spindle ?

Seems I need to lower the spindle out of the quill to do it ... I figure i'd ask

the PM community before I make a bigger job if i'm missing something simple.

Any help appreciated, Thanks !

Last edited: