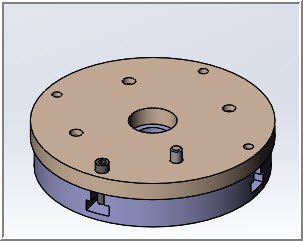

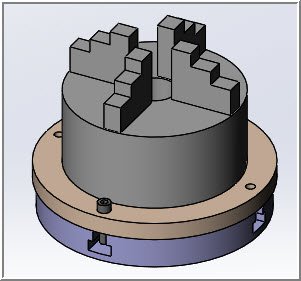

I've had a few requests for muzzle brakes and flash hiders. I had this little tilting 4" table with a 3" chuck. It did work, but I had to take things so slow to avoid chatter or completely knocking the work loose. Stronger, bigger, heavier iron was the answer. Turning the key is a little stiff, but I haven't cleaned or lubed it yet. I don't see why this won't serve the purpose just fine. Will I be building Pratt & Witney rocket engine parts with it ? No. Will it get me within a couple of thou if I take my time setting everything up just right, and keep it there while I do my cuts ? No doubt. The chuck and adapter plate are $240 USD shipped within the US. All said and done, including import fees, a little more shipping (I suspect), currency exchange...the usual stuff they saddle us poor Canadian guys with....LOL.... all said and done, it was $341.07 Canadian pesos, delivered to my door step. Still cheaper than any 8" chuck that I can buy here by half.