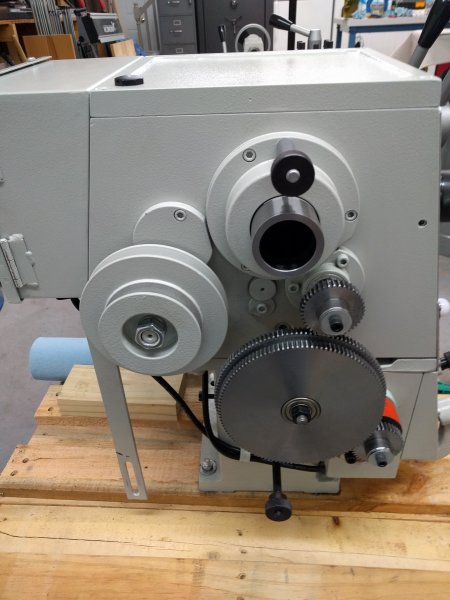

Okay, I spent a little time perusing the "studies" today on this topic and in allignment with Bob and David's advice, I have decided to give the following a trial. Because I have it on hand, I am going to Boeshield the gear sides to protect them from corrosion and then treat the gear cogs with CRC Industrial Extreme Duty Open Gear and Chain Lube.

View attachment 140446

The big advantage on this is the tackiness and content of this CRC product. It has significant amounts of graphite and molybdenum disulphide coupled with the heavy oil. It has a good reputation for this application and is specifically designated for open gears and chains. Downside is that it does not come in an aerosol can with a straw. Therefore I plan to spray an appropriate amount in container and brush it on the gears to avoid the mess. You will notice that even CRC describes it as a "Black Semi-Viscous Liquid". I have used powdered moly in the past in another application and it is truly nasty stuff in terms of a mess and stains. Here's the big component makeup from the Safety Data Sheet:

View attachment 140445

I am thinking that while this will be a bit messy it will provide the durable lubricity that one needs for the gears. I am hopeful that I will confirm the experience of others that it will not sling the lube everywhere under the cover.