Here's a few pictures of how I machined the dies for my HF 20T press.

Tom S.

Here's the male die with 60 deg. included angle. I don't have any pictures of the machining but it's essentially the same as the female die.

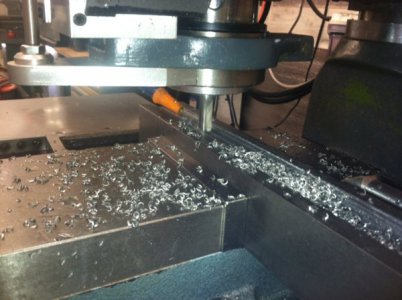

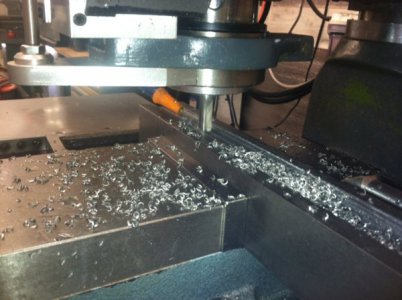

I roughed out the female die like so. Did it in two passes as my mill drill has about 18" of X travel.

I finish machined the male and female dies by clamping the vise to my tilting table.

And the finished product.

Tom S.

Here's the male die with 60 deg. included angle. I don't have any pictures of the machining but it's essentially the same as the female die.

I roughed out the female die like so. Did it in two passes as my mill drill has about 18" of X travel.

I finish machined the male and female dies by clamping the vise to my tilting table.

And the finished product.