- Joined

- Sep 22, 2010

- Messages

- 7,223

Hi Guys,

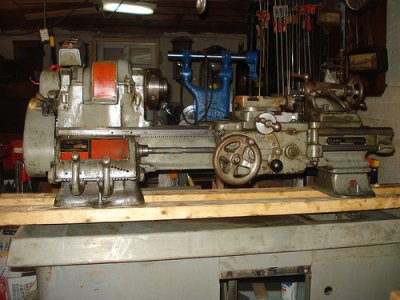

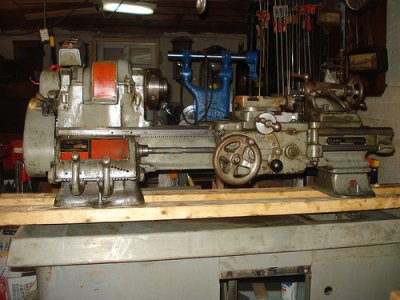

I have dreaded posting this. These are the BEFORE pictures- "pre-Nelson"

A few years ago, I bought a Heavy 10 and had it shipped in from Michigan.

It was a nice looking machine before I got my fool hands on it. I have photos of how it looked in my back yard.

Wanting to get it into the basement, and being a fool, I disassembled it. But I didn't stop there. I continued once it was downstairs.

I scarred up the spindle getting the old spindle gear off in order to install an extended spindle gear for the lever collet closer.

The ways, showing a few nicks.

The headstock outside, before I touched it.

The lathe on dollies and slinged for movement.

The old Clark contactor box.

The cabinet frame with as much steel as possible removed.

A view of the headstock inside.

Another view of the headstock in the basement.

Another view of the cabinet.

Another view of the ways.

The lathe bed outside.

Closeup of the headstock inside.

The carriage inside sitting on a drill press table.

The whole lathe inside bolted to some 2x4's.

Steel cabinet outside, steel being removed.

Steel cabinet outside, more steel gone.

Steel cabinet inside down to skeleton.

Lathe bed on a cooler outside.

The hole in the steel cabinet for the headstock belts.

I have dreaded posting this. These are the BEFORE pictures- "pre-Nelson"

A few years ago, I bought a Heavy 10 and had it shipped in from Michigan.

It was a nice looking machine before I got my fool hands on it. I have photos of how it looked in my back yard.

Wanting to get it into the basement, and being a fool, I disassembled it. But I didn't stop there. I continued once it was downstairs.

I scarred up the spindle getting the old spindle gear off in order to install an extended spindle gear for the lever collet closer.

The ways, showing a few nicks.

The headstock outside, before I touched it.

The lathe on dollies and slinged for movement.

The old Clark contactor box.

The cabinet frame with as much steel as possible removed.

A view of the headstock inside.

Another view of the headstock in the basement.

Another view of the cabinet.

Another view of the ways.

The lathe bed outside.

Closeup of the headstock inside.

The carriage inside sitting on a drill press table.

The whole lathe inside bolted to some 2x4's.

Steel cabinet outside, steel being removed.

Steel cabinet outside, more steel gone.

Steel cabinet inside down to skeleton.

Lathe bed on a cooler outside.

The hole in the steel cabinet for the headstock belts.

Last edited by a moderator: