F

f350ca

Forum Guest

Register Today

Like your work bench, from the surface up it looks just like mine.

Greg

Greg

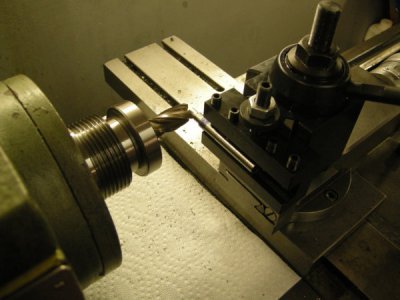

Hi. For what it's worth, I have a Harbor Freight 8x12 mini-lathe. I needed to cut key ways in a powered wheelchair axel shaft. My homemade milling attachement worked to perfection. I believe that you can get acceptalbe results milling with your lathe. Just my experience.I have only a lathe very heavy duty lathe, i've seen couple pictures of lathe milling attachment but don't know is this a useful tool, can i get any accuracy with this attachment ?