- Joined

- Nov 23, 2014

- Messages

- 2,606

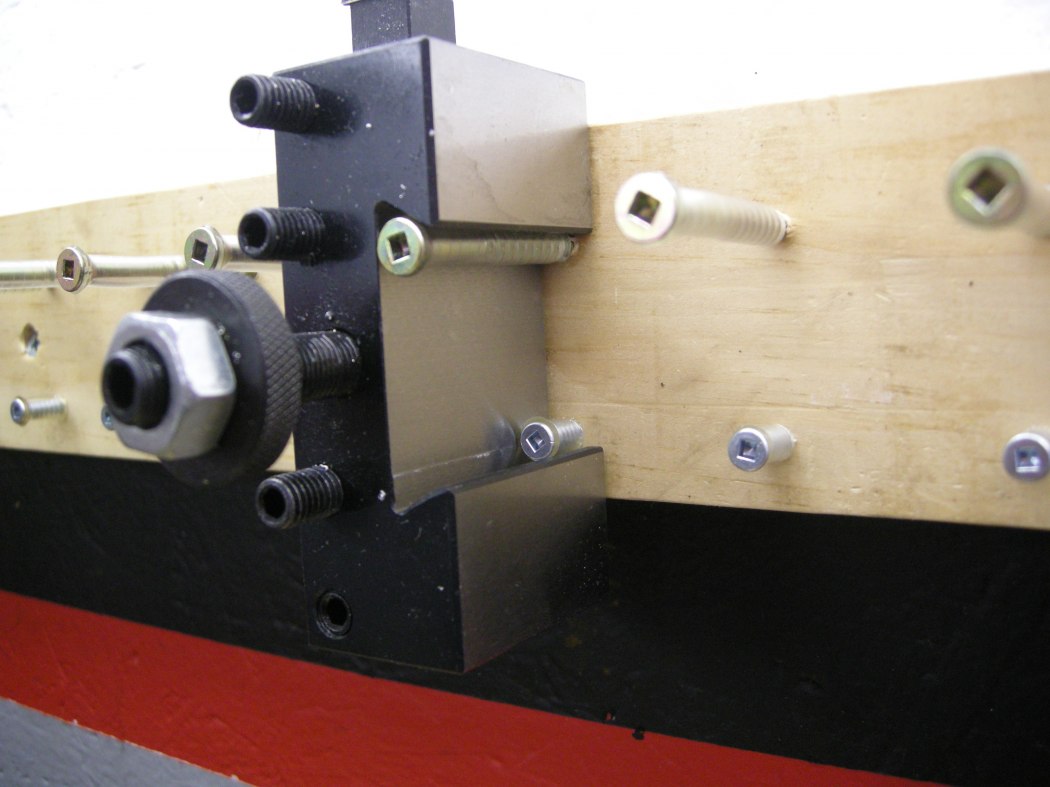

Found the original concept in POTD, so kudos to Roadie33 for the original idea. Here's the page with Mike's post.I really like my Grizzly G0709 lathe set up; good variety of quick change tool holders within an easy grasp. One of my other lathes is a Clausing 12 x 24 which usually has a 5C collet chuck mounted. The QC tool holders for it had been setting in a HF tool cart within an easy reach, but not as convenient as the Grizzly set up. The Clausing doesn’t have a back splash on it which leaves some hard to get to places to sweep up swarf on the back side of the lathe.

I “stole” the idea on a roll-around back splash/tool holder from another poster on this site. I couldn’t find the OP’s posting to give them proper credit but will if I eventually find it. Second best activity is reading through old postings on this site!

View attachment 239535 View attachment 239536 View attachment 239537 View attachment 239538 View attachment 239539 View attachment 239540

Bruce

http://hobby-machinist.com/threads/...-did-you-do-in-your-shop-today.14637/page-327