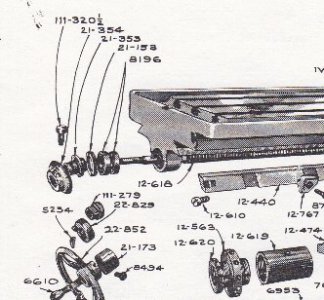

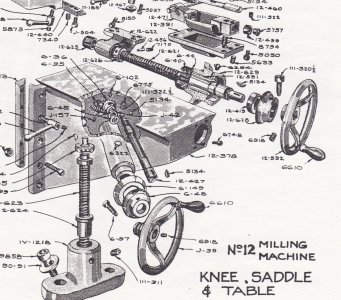

Hey folks. I've searched for info on this subject on many sites, can't seem to locate what I need. I've got a VN-12 that I've partially dissasembled, and want to get it stripped down a bit further for clean up and paint. Have removed the ram, table, motor, and now going after the knee and saddle. I've got the machine manual that shows the assembly breakdown, but not clear enough to define how to remove these. I've attempted to remove the feed screw with no success having removed the 4 screws and putting a puller on the shaft and the part that sits right behind the graduated dial. Got it to move a bit, but did not want to force the issue. Decided to ask those who may have been there and done it, instead of continuing onto dead ends. So can anyone please provide advise on the best approach for removing the saddle and knee on this machine. Thanks.