- Joined

- Aug 16, 2016

- Messages

- 193

Hello,

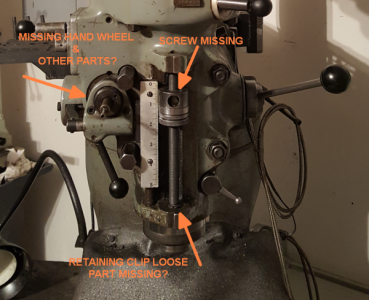

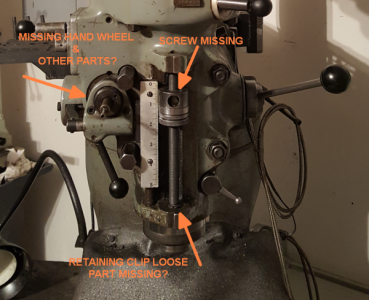

My Bridgeport was delivered Monday and I have not had a chance to do much to it other than a cursory once over. I noted a couple obvious problems with the quill stop and fine movement wheel, or lack thereof, below.

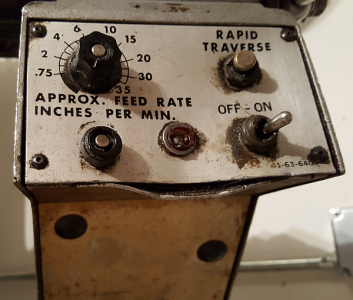

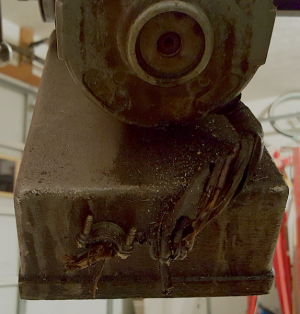

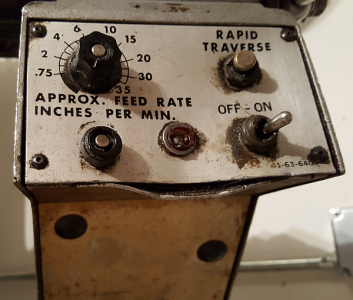

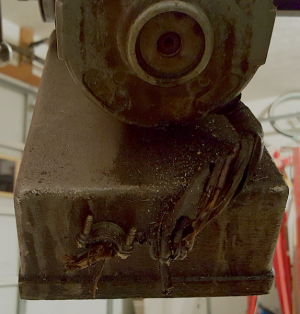

The power feed is totally botched, at a minimum the controls are. I am hoping the motor is still good.

Is there a concise document that I can use as a check list of things to check operationally and their order?

My Bridgeport was delivered Monday and I have not had a chance to do much to it other than a cursory once over. I noted a couple obvious problems with the quill stop and fine movement wheel, or lack thereof, below.

The power feed is totally botched, at a minimum the controls are. I am hoping the motor is still good.

Is there a concise document that I can use as a check list of things to check operationally and their order?

About the fine quill feed hand wheels, I agree not many people use them and they get lost or tossed. Thats why when I went to look at my mill and saw it had one still attached I knew that machine was a keeper! I looked for quite awhile to find one that wasn't abused, neglected, clapped out and needing a total overhaul. Check out this tool porn. Original paint....

About the fine quill feed hand wheels, I agree not many people use them and they get lost or tossed. Thats why when I went to look at my mill and saw it had one still attached I knew that machine was a keeper! I looked for quite awhile to find one that wasn't abused, neglected, clapped out and needing a total overhaul. Check out this tool porn. Original paint....